Iron in its pure form is a ductile gray metal that can be easily processed. And yet, for humans, the Fe element is more practical in combination with carbon and other impurities that allow the formation of metal alloys - steel and cast iron. 95% - this is exactly how much of all metal products produced on the planet contains iron as the main element.

Iron: history

The first iron products made by man are dated by scientists in the 4th millennium BC. e., and studies have shown that meteoric iron, which is characterized by a 5-30 percent nickel content, was used for their production. It’s interesting, but until humanity mastered the extraction of Fe by smelting it, iron was valued more than gold. This was explained by the fact that stronger and more reliable steel was much more suitable for the manufacture of tools and weapons than copper and bronze.

The ancient Romans learned how to produce the first cast iron: their furnaces could raise the temperature of the ore to 1400 o C, while 1100-1200 o C was enough for cast iron. Subsequently, they also obtained pure steel, the melting point of which, as is known, is 1535 degrees Celsius. Celsius.

Chemical properties of Fe

What does iron interact with? Iron interacts with oxygen, which is accompanied by the formation of oxides; with water in the presence of oxygen; with sulfuric and hydrochloric acids:

- 3Fe+2O2 = Fe3O4

- 4Fe+3O 2 +6H 2 O = 4Fe(OH) 3

- Fe+H 2 SO 4 = FeSO 4 +H 2

- Fe+2HCl = FeCl 2 +H 2

Also, iron reacts to alkalis only if they are melts of strong oxidizing agents. Iron does not react with oxidizing agents at normal temperatures, but always begins to react when it increases.

Use of iron in construction

The use of iron in the construction industry today cannot be overestimated, because metal structures are the basis of absolutely any modern building. In this area, Fe is used in common steels, cast iron and wrought iron. This element is found everywhere, from critical structures to anchor bolts and nails.

The construction of building structures made of steel is much cheaper, and we can also talk about higher construction rates. This markedly increases the use of iron in construction, while the industry itself is embracing the use of new, more efficient and reliable Fe-based alloys.

Use of iron in industry

The use of iron and its alloys - cast iron and steel - is the basis of modern machine-tool, aircraft, instrument making and the manufacture of other equipment. Thanks to Fe cyanides and oxides, the paint and varnish industry functions; iron sulfates are used in water treatment. Heavy industry is completely unthinkable without the use of Fe+C-based alloys. In a word, Iron is an irreplaceable, but at the same time accessible and relatively inexpensive metal, which, as part of its alloys, has an almost unlimited scope of application.

Use of iron in medicine

It is known that every adult contains up to 4 grams of iron. This element is extremely important for the functioning of the body, in particular for health. circulatory system(hemoglobin in red blood cells). There are many iron-based medications that can increase Fe levels to prevent the development of iron deficiency anemia.

Do you know that iron protects the planet from “cosmic attacks”? Thanks to huge accumulations of this element, the Earth's magnetic field is formed. Like a screen, the field protects it from asteroids...

Iron plays a role not only in such global things, but also in our everyday life: steel and most alloys are created precisely on the basis of this element. Thus, everything from cutlery to cars to microelectronics could not work without hardware.

Finally, our life would be impossible without it, since this mineral is part of hemoglobin - the contents of red blood cells, thanks to which tissues are able to use oxygen. This wonderful element hides many more useful properties. Read more about the functions of iron for our health in this article.

Iron content in products (per 100 g):

Liver 10-20 mg

Yeast 18 mg

Sea kale 16 mg

Lentils 12 mg

Buckwheat 8.2 mg

Yolk 7.2 mg

Rabbit 4.4 mg

Black caviar 2.5 mg

What is iron?

It's metal. In organs and tissues, iron is found in approximately 3-5 grams. This is not much, but such a small dose is enough for the body to successfully continue its existence. Four-fifths of all iron is contained in hemoglobin, the rest is scattered throughout the body and distributed in the liver, muscles, bones, etc. Some of the internal iron is included in enzymes.

Over time, a natural loss of the mineral occurs, and therefore a person needs a constant supply of some dosages of iron. It is lost in urine and sweat; in women, iron consumption is also associated with monthly losses during menstruation.

Iron-rich foods

The element is so widespread in nature that iron is present in most foods. The best sources are animals - meat and liver. In them, iron is in the most digestible form. There is usually less of it in plant foods than in animal foods, but this is also an important source of the mineral. It is present in citrus fruits, pomegranates, beets, buckwheat, legumes, nuts, pumpkin, apples, seaweed, and persimmons.

Daily iron requirement

As a rule, men have a greater need for vitamins and minerals than women, but in this case this is not the case: women need higher dosages of iron. They require 18 mg of the mineral, while men require about 10 mg. For children, the norm is not precisely determined; according to various sources, it can range from 4 to 15 mg.

Increased iron requirement

An increased need for iron is inherent in the following groups of people:

An increased need for iron is inherent in the following groups of people:

Women during the period after menstruation. Blood loss, even if small, requires compensation for the hemoglobin content in the blood.

. Pregnant and lactating. During pregnancy, a significant consumption of iron is carried out to build the fetal body, and nursing mothers spend their iron on feeding the child (it passes into breast milk). Literally every second pregnant woman shows signs of iron deficiency, which indicates a significant increase in the need for this element in expectant mothers.

. After injuries, blood loss, serious surgical operations.

Iron is a very valuable element. In this regard, the body has learned to reuse it. During the natural destruction of old red blood cells, special carrier proteins capture the released iron and transport it to the hematopoietic organs, where it is used again.

However, the loss of the mineral is still quite large, so many people require additional iron supplementation in everyday life. If you have an increased need for this element, you should start taking food supplements containing this element.

Absorption of iron from food

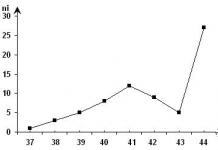

Even under ideal conditions, no more than 10% of ingested iron is absorbed from food. There are a number of factors that further reduce this figure. At the same time, there are certain factors that increase the absorption of the mineral. What determines the degree of iron absorption?

Even under ideal conditions, no more than 10% of ingested iron is absorbed from food. There are a number of factors that further reduce this figure. At the same time, there are certain factors that increase the absorption of the mineral. What determines the degree of iron absorption?

1. Source. Animal products contain iron in an easy-to-absorb divalent form. In plants it is trivalent. In order to assimilate it and put it to use, the body must expend energy to restore the mineral to its divalent form. That is why most of the iron supplied with buckwheat or pomegranate juice does not benefit the body.

2. Digestive health. With reduced acidity of gastric juice, gastritis and enteritis, iron absorption is significantly reduced. It is optimal for a healthy digestive tract.

3. Food composition.

4. Iron is better absorbed in the presence of vitamin C, organic acids of vegetables and fruits, amino acids lysine and histidine, as well as some carbohydrates such as fructose and sorbitol. Thus, meat and liver should always be combined with a fresh vegetable salad.

5. Iron is less easily absorbed in the presence of tannins, dietary fiber (they “collect” iron molecules and remove them from the body), phytin, and oxalic acid. This means that if you are looking to get more iron, it is recommended to avoid eating foods such as legumes, sorrel, spinach, and bran too often. Calcium is a fairly strong antagonist of iron; products containing it (mainly dairy) inhibit its absorption.

Biological role of iron

The functions of iron are:

It is an indispensable element for hematopoiesis, the raw material for the formation of the respiratory pigment hemoglobin and the formation of red blood cells.

. Important for the synthesis of thyroid hormones

. Strengthens the immune system, helps increase the body's defenses

. Improves the functioning of certain vitamins such as vitamin B6, B12, B9

. Improves the effects of a number of trace elements such as cobalt, manganese, copper

. Part of enzymes that ensure the neutralization of harmful substances in the body

. Provides the ability for tissues to breathe, and this gives not only a healing, but also a cosmetic effect. With normal intake of iron into the body, a person’s skin, hair, and nails remain in good condition.

. Protects against overwork and chronic fatigue

. Has great value in the functioning of the nervous system.

Signs of iron deficiency

A deficiency of the mineral and the need for regular iron supplementation is extremely common. The very first and main sign of element deficiency in the body is anemia.

A deficiency of the mineral and the need for regular iron supplementation is extremely common. The very first and main sign of element deficiency in the body is anemia.

A decrease in the number of red blood cells and the level of hemoglobin in the blood leads to the following symptoms: weakness, rapid onset of fatigue, instability to physical activity, constipation or diarrhea, disturbances of appetite and taste, numbness and chilliness in the extremities, pale and dry skin, deterioration of nails, hair loss , weakened immune system, etc. Often it is these signs that allow us to guess about iron deficiency in the body. The person goes to the doctor, is examined and anemia is detected.

Signs of excess iron

Even when eating foods containing high concentrations of iron, iron excess does not occur. This is due to the fact that the body independently “filters” excess mineral compounds and takes exactly as much iron as it needs.

It is much more difficult for him to resist the ultra-high dosages of iron supplied with drugs. If iron-containing products and nutritional supplements are used too intensively, poisoning may occur. It makes itself felt by vomiting, headache, stool disorders and other symptoms.

Excess iron is also seen in a rare condition called hemochromatosis. With this disease, the body carries out a pathological accumulation of iron, which is manifested by serious disorders of the liver and other organs.

Factors influencing iron content in foods

If long time carry out culinary processing of products, the content of digestible iron in them decreases, since it turns into a form that is inaccessible for absorption. Therefore, if you buy meat or liver, choose products highest quality, which will not be too tough and which will not need to be boiled or fried for too long.

Iron is a chemical element

1. Position of iron in the periodic table chemical elements and the structure of its atom

Iron is a d element VIII group; serial number – 26; atomic mass Ar(Fe ) = 56; atomic composition: 26 protons; 30 – neutrons; 26 – electrons.

Atomic structure diagram:

Electronic formula: 1s 2 2s 2 2p 6 3s 2 3p 6 3d 6 4s 2

Metal average activity, reducing agent:

Fe 0 -2 e - → Fe +2 , the reducing agent is oxidized

Fe 0 -3 e - → Fe +3 , the reducing agent is oxidized

Main oxidation states: +2, +3

2. Iron prevalence

Iron is one of the most common elements in nature . IN earth's crust his mass fraction is 5.1%, according to this indicator it second only to oxygen, silicon and aluminum. A lot of iron is also found in celestial bodies, as determined by spectral analysis. In samples of lunar soil delivered by the Luna automatic station, iron was found in an unoxidized state.

Iron ores are quite widespread on Earth. The names of the mountains in the Urals speak for themselves: Vysokaya, Magnitnaya, Zheleznaya. Agrochemists find iron compounds in soils.

Iron is a component of most rocks. To obtain iron, iron ores with an iron content of 30-70% or more are used.

The main iron ores are :

magnetite(magnetic iron ore) – Fe3O4 contains 72% iron, deposits are found on Southern Urals, Kursk magnetic anomaly:

|

|

|

hematite(iron sheen, bloodstone)– Fe2O3 contains up to 65% iron, such deposits are found in the Krivoy Rog region:

|

|

|

limonite(brown iron ore) – Fe 2 O 3* nH 2 O contains up to 60% iron, deposits are found in Crimea:

pyrite(sulfur pyrite, iron pyrite, cat gold) – FeS 2 contains approximately 47% iron, deposits are found in the Urals.

3. The role of iron in the life of humans and plants

Biochemists have discovered the important role of iron in the life of plants, animals and humans. Being part of an extremely complex construction organic compound, called hemoglobin, iron determines the red color of this substance, which in turn determines the color of human and animal blood. The body of an adult contains 3 g of pure iron, 75% of which is part of hemoglobin. The main role of hemoglobin is to transport oxygen from the lungs to the tissues, and in the opposite direction - CO 2.

Plants also need iron. It is part of the cytoplasm and participates in the process of photosynthesis. Plants grown on a substrate that does not contain iron have white leaves. A small addition of iron to the substrate and they turn green. Moreover, it is worth smearing a white sheet with a solution of salt containing iron, and soon the smeared area turns green.

So, for the same reason - the presence of iron in juices and tissues - the leaves of plants turn cheerfully green and a person’s cheeks brightly blush.

4. Physical properties of iron.

Iron is a silvery-white metal with a melting point of 1539 o C. It is very ductile, therefore it is easily processed, forged, rolled, stamped. Iron has the ability to be magnetized and demagnetized, therefore it is used as electromagnet cores in various electrical machines and devices. It can be given greater strength and hardness by thermal and mechanical methods, for example, by hardening and rolling.

There are chemically pure and commercially pure iron. Technically pure iron is essentially low-carbon steel; it contains 0.02-0.04% carbon, and even less oxygen, sulfur, nitrogen and phosphorus. Chemically pure iron contains less than 0.01% impurities. Chemically pure iron - silver-gray, shiny, appearance a metal very similar to platinum. Chemically pure iron is resistant to corrosion and has good resistance to acids. However, insignificant amounts of impurities deprive it of these precious properties.

5. Getting iron

Reduction from oxides with coal or carbon monoxide (II), as well as hydrogen:

FeO + C = Fe + CO

Fe 2 O 3 + 3CO = 2Fe + 3CO 2

Fe 2 O 3 + 3H 2 = 2Fe + 3H 2 O

Experiment "Production of iron by aluminothermy"

6. Chemical properties gland

As a secondary subgroup element, iron can exhibit several oxidation states. We will consider only compounds in which iron exhibits oxidation states +2 and +3. Thus, we can say that iron has two series of compounds, in which it is di- and trivalent.

1) In air, iron easily oxidizes in the presence of moisture (rusting):

4Fe + 3O 2 + 6H 2 O = 4Fe(OH) 3

2) Hot iron wire burns in oxygen, forming scale - iron oxide (II,III) - a black substance:

3Fe + 2O 2 = Fe 3 O 4

Coxygen in moist air is formed Fe 2 O 3 * nH 2 O

Experiment "Interaction of iron with oxygen"

3) At high temperatures (700–900°C), iron reacts with water vapor:

3Fe + 4H 2 O t˚C → Fe 3 O 4 + 4H 2

4) Iron reacts with non-metals when heated:

Fe + S t˚C → FeS

5) Iron easily dissolves in hydrochloric and dilute sulfuric acids under normal conditions:

Fe + 2HCl = FeCl 2 + H 2

Fe + H 2 SO 4 (dil.) = FeSO 4 + H 2

6) Iron dissolves in concentrated oxidizing acids only when heated

2Fe + 6H 2 SO 4 (conc. .) t˚C → Fe 2 (SO 4) 3 + 3SO 2 + 6H 2 O

Fe + 6HNO 3 (conc. .) t˚C → Fe(NO 3) 3 + 3NO 2 + 3H 2 OIron(III)

7. Use of iron.

The bulk of the iron produced in the world is used to produce cast iron and steel - alloys of iron with carbon and other metals. Cast irons contain about 4% carbon. Steels contain less than 1.4% carbon.

Cast irons are necessary for the production of various castings - heavy machine frames, etc.

Cast iron products

Steels are used to make machines, various building materials, beams, sheets, rolled products, rails, tools and many other products. To produce various grades of steel, so-called alloying additives are used, which are various metals: M

Simulator No. 2 - Genetic series Fe 3+

Simulator No. 3 - Equations of reactions of iron with simple and complex substances

Tasks for consolidation

No. 1. Write down reaction equations for the production of iron from its oxides Fe 2 O 3 and Fe 3 O 4, using as a reducing agent:

a) hydrogen;

b) aluminum;

c) carbon monoxide (II).

For each reaction, create an electronic balance.

No. 2. Carry out transformations according to the scheme:

Fe 2 O 3 -> Fe - +H2O, t -> X - +CO, t -> Y - +HCl ->Z

Name products X, Y, Z?

This article will talk about iron, its chemical and physical properties. They are of great importance for determining the method of transportation of iron, its conditions of storage, production, smelting, etc.

Iron is one of the most popular metals. But this is often called an alloy with some kind of admixture, for example, carbon. This helps maintain the ductility and softness of the metal itself. An indicator in such a composition will be the amount of pure metal, carbon and impurities.

For steel smelting, a metallization method is used, which helps the product become more resistant to external influences, such as erosion, corrosion, and wear. In this case, the content of additional impurities may vary.

Carbon

The percentage of carbon content in the alloy can range from 0.2% to 10%. It depends on the method of iron recovery. Moreover, the quantity and degree of metallization can vary very widely. In gaseous reduction processes, filamentous carbon is deposited from the gas phase onto the surface of the iron. But the reaction is not completely completed, and the product that has undergone metallization has soot formed from carbon on its surface and in its pores.

Phosphorus

In the process of direct reduction of iron, the amount of phosphorus does not decrease, and the percentage of its content during metallization is equal to its amount in the feedstock. This can be reduced by complete beneficiation of the ore used for the reduction process. Moreover, the ratio of phosphorus and iron depends on an increase in the percentage of iron, which leads to a decrease in the percentage of phosphorus content. In most formulations it is 0.010-0.020%, rarely 0.030%.

Sulfur

The raw material for direct reduction of iron is often pellets that have not been fluxed, since most of the sulfur has been removed by oxidative roasting, leaving the main source of sulfur as the reducing agent.

With the initial solid reducing agent, the amount of sulfur in the metallized material may be high. Then its reduction can be achieved by adding limestone and dolomite.

In the case of a gaseous reducing agent, the output is a product with a low percentage of sulfur, up to 0.003.

Nitrogen and hydrogen

Nitrogen is contained in small quantities in ore, which determines its small percentage in metallized materials, up to 0.003%. The amount of hydrogen reaches 150 cubic meters. cm per 100 grams, and in steel its percentage is the same as in the smelting of scrap.

Non-ferrous metals

The amount of non-ferrous metals, namely nickel, chromium, lead, copper, has the composition of direct reduced iron, and is often low due to the purity of the raw materials. This indicator of sponge iron can be compared with cast iron. The only difference will be that cast iron contains chromium in reduced form.

Titanium, chromium, vanadium are found in metallized pellets as part of oxides. During the smelting process, it is quite simple to organize the possibility of preventing them from being recovered from the slag. This makes it possible to obtain a metal containing a low percentage of titanium, chromium and, possibly, manganese.

Iron, the composition of which includes tin, lead, zinc and other non-ferrous metals, and in a small and stable percentage, is formed when oxidative process pellet roasting, direct iron reduction and smelting. All this is due to the small amount of impurities of these metals in the ore, as well as their partial removal.

It has been determined that zinc removal is possible during metallization and smelting. Lead evaporates during firing and reduction, but to a small extent, and the main thing is the smelting process. Tin, like antimony, is difficult to remove from the composition due to its low content, or even turns into metal. Laboratory studies have shown that what iron is made of is determined by the amount of non-ferrous metals as impurities. Their percentage ranges from less than 0.01, both in steel containing nickel, chromium and copper, to less than 0.001 in compositions with tin, lead, arsenic, antimony and zinc.

Iron is an element of the secondary subgroup of the eighth group of the fourth period periodic table chemical elements of D.I. Mendeleev with atomic number 26. Indicated by the symbol Fe (lat. Ferrum). One of the most common metals in the earth's crust (second place after aluminum). Medium activity metal, reducing agent.

Main oxidation states - +2, +3

The simple substance iron is a malleable silver-white metal with high chemical reactivity: iron quickly corrodes when high temperatures ah or with high humidity in the air. IN pure oxygen iron burns, and in a finely dispersed state it spontaneously ignites in air.

Chemical properties of a simple substance - iron:

Rusting and burning in oxygen

1) In air, iron easily oxidizes in the presence of moisture (rusting):

4Fe + 3O 2 + 6H 2 O → 4Fe(OH) 3

Hot iron wire burns in oxygen, forming scale - iron oxide (II, III):

3Fe + 2O 2 → Fe 3 O 4

3Fe+2O 2 →(Fe II Fe 2 III)O 4 (160 °C)

2) At high temperatures (700–900°C), iron reacts with water vapor:

3Fe + 4H 2 O – t° → Fe 3 O 4 + 4H 2

3) Iron reacts with non-metals when heated:

2Fe+3Cl 2 →2FeCl 3 (200 °C)

Fe + S – t° → FeS (600 °C)

Fe+2S → Fe +2 (S 2 -1) (700°C)

4) In the voltage series, it is to the left of hydrogen, reacts with dilute acids HCl and H 2 SO 4, and iron(II) salts are formed and hydrogen is released:

Fe + 2HCl → FeCl 2 + H 2 (reactions are carried out without air access, otherwise Fe +2 is gradually converted by oxygen to Fe +3)

Fe + H 2 SO 4 (diluted) → FeSO 4 + H 2

In concentrated oxidizing acids, iron dissolves only when heated; it immediately transforms into the Fe 3+ cation:

2Fe + 6H 2 SO 4 (conc.) – t° → Fe 2 (SO 4) 3 + 3SO 2 + 6H 2 O

Fe + 6HNO 3 (conc.) – t° → Fe(NO 3) 3 + 3NO 2 + 3H 2 O

(in the cold, concentrated nitrogen and sulfuric acid passivate

An iron nail immersed in a bluish solution of copper sulfate gradually becomes coated with a coating of red metallic copper.

5) Iron displaces metals located to the right of it from solutions of their salts.

Fe + CuSO 4 → FeSO 4 + Cu

The amphoteric properties of iron appear only in concentrated alkalis during boiling:

Fe + 2NaOH (50%) + 2H 2 O= Na 2 ↓+ H 2

and a precipitate of sodium tetrahydroxoferrate(II) is formed.

Technical hardware- alloys of iron and carbon: cast iron contains 2.06-6.67% C, steel 0.02-2.06% C, other natural impurities (S, P, Si) and artificially introduced special additives (Mn, Ni, Cr) are often present, which gives iron alloys technically useful properties - hardness, thermal and corrosion resistance, malleability, etc. .

Blast furnace iron production process

The blast furnace process for producing cast iron consists of the following stages:

a) preparation (roasting) of sulfide and carbonate ores - conversion to oxide ore:

FeS 2 →Fe 2 O 3 (O 2,800°C, -SO 2) FeCO 3 →Fe 2 O 3 (O 2,500-600°C, -CO 2)

b) combustion of coke with hot blast:

C (coke) + O 2 (air) → CO 2 (600-700 ° C) CO 2 + C (coke) ⇌ 2 CO (700-1000 ° C)

c) reduction of oxide ore with carbon monoxide CO sequentially:

Fe2O3 →(CO)(Fe II Fe 2 III) O 4 →(CO) FeO →(CO) Fe

d) carburization of iron (up to 6.67% C) and melting of cast iron:

Fe (t ) →(C(coke)900-1200°C) Fe (liquid) (cast iron, melting point 1145°C)

Cast iron always contains cementite Fe 2 C and graphite in the form of grains.

Steel production

The conversion of cast iron into steel is carried out in special furnaces (converter, open-hearth, electric), which differ in the heating method; process temperature 1700-2000 °C. Blowing air enriched with oxygen leads to the burning out of excess carbon, as well as sulfur, phosphorus and silicon in the form of oxides from the cast iron. In this case, the oxides are either captured in the form of exhaust gases (CO 2, SO 2), or are bound into an easily separated slag - a mixture of Ca 3 (PO 4) 2 and CaSiO 3. To produce special steels, alloying additives of other metals are introduced into the furnace.

Receipt pure iron in industry - electrolysis of a solution of iron salts, for example:

FeСl 2 → Fe↓ + Сl 2 (90°С) (electrolysis)

(there are others special methods, including the reduction of iron oxides with hydrogen).

Pure iron is used in the production of special alloys, in the manufacture of cores of electromagnets and transformers, cast iron - in the production of castings and steel, steel - as structural and tool materials, including wear-, heat- and corrosion-resistant ones.

Iron(II) oxide F EO . An amphoteric oxide with a high predominance of basic properties. Black, has an ionic structure Fe 2+ O 2- . When heated, it first decomposes and then forms again. It is not formed when iron burns in air. Does not react with water. Decomposes with acids, fuses with alkalis. Slowly oxidizes in humid air. Reduced by hydrogen and coke. Participates in the blast furnace process of iron smelting. It is used as a component of ceramics and mineral paints. Equations of the most important reactions:

4FeO ⇌(Fe II Fe 2 III) + Fe (560-700 °C, 900-1000 °C)

FeO + 2HC1 (diluted) = FeC1 2 + H 2 O

FeO + 4HNO 3 (conc.) = Fe(NO 3) 3 +NO 2 + 2H 2 O

FeO + 4NaOH = 2H 2 O + Na 4FeO3(red.) trioxoferrate(II)(400-500 °C)

FeO + H 2 =H 2 O + Fe (extra pure) (350°C)

FeO + C (coke) = Fe + CO (above 1000 °C)

FeO + CO = Fe + CO 2 (900°C)

4FeO + 2H 2 O (moisture) + O 2 (air) →4FeO(OH) (t)

6FeO + O 2 = 2(Fe II Fe 2 III) O 4 (300-500°C)

Receipt V laboratories: thermal decomposition of iron (II) compounds without air access:

Fe(OH) 2 = FeO + H 2 O (150-200 °C)

FeCO3 = FeO + CO 2 (490-550 °C)

Diiron(III) oxide - iron( II ) ( Fe II Fe 2 III)O 4 . Double oxide. Black, has the ionic structure Fe 2+ (Fe 3+) 2 (O 2-) 4. Thermally stable up to high temperatures. Does not react with water. Decomposes with acids. Reduced by hydrogen and hot iron. Participates in the blast furnace process of cast iron production. Used as a component of mineral paints ( red lead), ceramics, colored cement. Product of special oxidation of the surface of steel products ( blackening, bluing). The composition corresponds to brown rust and dark scale on iron. The use of the gross formula Fe 3 O 4 is not recommended. Equations of the most important reactions:

2(Fe II Fe 2 III)O 4 = 6FeO + O 2 (above 1538 °C)

(Fe II Fe 2 III) O 4 + 8НС1 (dil.) = FeС1 2 + 2FeС1 3 + 4Н 2 O

(Fe II Fe 2 III) O 4 +10HNO 3 (conc.) = 3Fe(NO 3) 3 + NO 2 + 5H 2 O

(Fe II Fe 2 III) O 4 + O 2 (air) = 6 Fe 2 O 3 (450-600 ° C)

(Fe II Fe 2 III)O 4 + 4H 2 = 4H 2 O + 3Fe (extra pure, 1000 °C)

(Fe II Fe 2 III) O 4 + CO = 3 FeO + CO 2 (500-800°C)

(Fe II Fe 2 III)O4 + Fe ⇌4FeO (900-1000 °C, 560-700 °C)

Receipt: combustion of iron (see) in air.

magnetite.

Iron(III) oxide F e 2 O 3 . Amphoteric oxide with a predominance of basic properties. Red-brown, has an ionic structure (Fe 3+) 2 (O 2-) 3. Thermally stable up to high temperatures. It is not formed when iron burns in air. Does not react with water, brown amorphous hydrate Fe 2 O 3 nH 2 O precipitates from the solution. Reacts slowly with acids and alkalis. Reduced by carbon monoxide, molten iron. Fuses with oxides of other metals and forms double oxides - spinels(technical products are called ferrites). It is used as a raw material in the smelting of cast iron in the blast furnace process, a catalyst in the production of ammonia, a component of ceramics, colored cements and mineral paints, in thermite welding of steel structures, as a carrier of sound and image on magnetic tapes, as a polishing agent for steel and glass.

Equations of the most important reactions:

6Fe 2 O 3 = 4(Fe II Fe 2 III)O 4 +O 2 (1200-1300 °C)

Fe 2 O 3 + 6НС1 (dil.) →2FeС1 3 + ЗН 2 O (t) (600°С,р)

Fe 2 O 3 + 2NaOH (conc.) →H 2 O+ 2 NAFeO 2 (red)dioxoferrate(III)

Fe 2 O 3 + MO = (M II Fe 2 II I) O 4 (M = Cu, Mn, Fe, Ni, Zn)

Fe 2 O 3 + ZN 2 = ZN 2 O+ 2Fe (extra pure, 1050-1100 °C)

Fe 2 O 3 + Fe = 3FeO (900 °C)

3Fe 2 O 3 + CO = 2(Fe II Fe 2 III)O 4 + CO 2 (400-600 °C)

Receipt in the laboratory - thermal decomposition of iron (III) salts in air:

Fe 2 (SO 4) 3 = Fe 2 O 3 + 3SO 3 (500-700 °C)

4(Fe(NO 3) 3 9 H 2 O) = 2Fe a O 3 + 12NO 2 + 3O 2 + 36H 2 O (600-700 °C)

In nature - iron oxide ores hematite Fe 2 O 3 and limonite Fe 2 O 3 nH 2 O

Iron(II) hydroxide F e(OH) 2 . Amphoteric hydroxide with a predominance of basic properties. White (sometimes with a greenish tint), Fe-OH bonds are predominantly covalent. Thermally unstable. Easily oxidizes in air, especially when wet (it darkens). Insoluble in water. Reacts with dilute acids and concentrated alkalis. Typical reducer. An intermediate product in the rusting of iron. It is used in the manufacture of the active mass of iron-nickel batteries.

Equations of the most important reactions:

Fe(OH) 2 = FeO + H 2 O (150-200 °C, atm.N 2)

Fe(OH) 2 + 2HC1 (dil.) = FeC1 2 + 2H 2 O

Fe(OH) 2 + 2NaOH (> 50%) = Na 2 ↓ (blue-green) (boiling)

4Fe(OH) 2 (suspension) + O 2 (air) →4FeO(OH)↓ + 2H 2 O (t)

2Fe(OH) 2 (suspension) +H 2 O 2 (diluted) = 2FeO(OH)↓ + 2H 2 O

Fe(OH) 2 + KNO 3 (conc.) = FeO(OH)↓ + NO+ KOH (60 °C)

Receipt: precipitation from solution with alkalis or ammonia hydrate in an inert atmosphere:

Fe 2+ + 2OH (dil.) = Fe(OH) 2 ↓

Fe 2+ + 2(NH 3 H 2 O) = Fe(OH) 2 ↓+ 2NH 4

Iron metahydroxide F eO(OH). Amphoteric hydroxide with a predominance of basic properties. Light brown, Fe - O and Fe - OH bonds are predominantly covalent. When heated, it decomposes without melting. Insoluble in water. Precipitates from solution in the form of a brown amorphous polyhydrate Fe 2 O 3 nH 2 O, which, when kept under dilute alkaline solution or upon drying it turns into FeO(OH). Reacts with acids and solid alkalis. Weak oxidizing and reducing agent. Sintered with Fe(OH) 2. An intermediate product in the rusting of iron. It is used as a base for yellow mineral paints and enamels, an absorber for waste gases, and a catalyst in organic synthesis.

The compound of composition Fe(OH) 3 is unknown (not obtained).

Equations of the most important reactions:

Fe 2 O 3 . nH 2 O→( 200-250 °C, —H 2 O) FeO(OH)→( 560-700° C in air, -H2O)→Fe 2 O 3

FeO(OH) + ZNS1 (dil.) = FeC1 3 + 2H 2 O

FeO(OH)→ Fe 2 O 3 . nH 2 O-colloid(NaOH (conc.))

FeO(OH)→ Na 3 [Fe(OH) 6 ]white, Na 5 and K 4 respectively; in both cases, a blue product of the same composition and structure, KFe III, precipitates. In the laboratory this precipitate is called Prussian blue, or turnbull blue:

Fe 2+ + K + + 3- = KFe III ↓

Fe 3+ + K + + 4- = KFe III ↓

Chemical names of the starting reagents and reaction products:

K 3 Fe III - potassium hexacyanoferrate (III)

K 4 Fe III - potassium hexacyanoferrate (II)

КFe III - iron (III) potassium hexacyanoferrate (II)

In addition, a good reagent for Fe 3+ ions is the thiocyanate ion NСS -, iron (III) combines with it, and a bright red (“bloody”) color appears:

Fe 3+ + 6NCS - = 3-

This reagent (for example, in the form of KNCS salt) can even detect traces of iron (III) in tap water if it passes through iron pipes coated with rust on the inside.