Organic matter is a chemical compound that contains carbon. The only exceptions are carbonic acid, carbides, carbonates, cyanides and carbon oxides.

Story

The term “organic substances” itself appeared in the everyday life of scientists at the stage early development chemistry. At that time, vitalistic worldviews dominated. This was a continuation of the traditions of Aristotle and Pliny. During this period, pundits were busy dividing the world into living and nonliving. Moreover, all substances without exception were clearly divided into mineral and organic. It was believed that a special “force” was needed to synthesize compounds of “living” substances. It is inherent in all living beings, and without it it cannot be formed organic elements they can't.

This is funny for modern science the statement prevailed for a very long time, until in 1828 Friedrich Wöhler empirically didn't refute it. He was able to obtain organic urea from inorganic ammonium cyanate. This pushed chemistry forward. However, the division of substances into organic and inorganic has been preserved in the present tense. It forms the basis of classification. Almost 27 million are known organic compounds.

Why are there so many organic compounds?

Organic matter is, with some exceptions, a carbon compound. This is actually a very interesting element. Carbon is capable of forming chains from its atoms. It is very important that the connection between them is stable.

In addition, carbon in organic matter ah exhibits valence - IV. It follows from this that this element is capable of forming not only single, but also double and triple bonds with other substances. As their multiplicity increases, the chain consisting of atoms will become shorter. At the same time, the stability of the connection only increases.

Carbon also has the ability to form flat, linear and three-dimensional structures. This is why there are so many different organic substances in nature.

Compound

As mentioned above, organic matter is carbon compounds. And this is very important. arise when it is associated with almost any element periodic table. In nature, most often their composition (in addition to carbon) includes oxygen, hydrogen, sulfur, nitrogen and phosphorus. The remaining elements are much less common.

Properties

So, organic matter is a carbon compound. However, there are several important criteria that it must meet. All substances of organic origin have common properties:

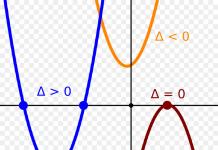

1. The different typology of bonds existing between atoms certainly leads to the appearance of isomers. First of all, they are formed when carbon molecules combine. Isomers are different substances that have one molecular weight and composition, but different chemical and physical properties. This phenomenon is called isomerism.

2. Another criterion is the phenomenon of homology. These are series of organic compounds, in which the formula of neighboring substances differs from the previous ones by one CH 2 group. This important property is used in materials science.

What classes of organic substances are there?

Organic compounds include several classes. They are known to everyone. lipids and carbohydrates. These groups can be called biological polymers. They are involved in metabolism cellular level in any organism. Also included in this group are nucleic acids. So we can say that organic matter is what we eat every day, what we are made of.

Squirrels

Proteins are made up of structural components- amino acids. These are their monomers. Proteins are also called proteins. About 200 types of amino acids are known. All of them are found in living organisms. But only twenty of them are components of proteins. They are called basic. But in the literature you can also find less popular terms - proteinogenic and protein-forming amino acids. The formula of an organic substance of this class contains amine (-NH 2) and carboxyl (-COOH) components. They are connected to each other by the same carbon bonds.

Functions of proteins

Proteins perform many important functions in the body of plants and animals. But the main one is structural. Proteins are the main components cell membrane and matrix of organelles in cells. In our body, all the walls of arteries, veins and capillaries, tendons and cartilage, nails and hair consist mainly of different proteins.

The next function is enzymatic. Proteins act as enzymes. They catalyze chemical reactions in the body. They are responsible for the breakdown of nutritional components in the digestive tract. In plants, enzymes fix the position of carbon during photosynthesis.

Some transport various substances in the body, such as oxygen. Organic matter is also capable of attaching to them. This is how the transport function is carried out. Proteins carry metal ions, fatty acids, hormones and, of course, carbon dioxide and hemoglobin through blood vessels. Transport also occurs at the intercellular level.

Protein compounds - immunoglobulins - are responsible for performing a protective function. These are blood antibodies. For example, thrombin and fibrinogen are actively involved in the coagulation process. Thus, they prevent large blood loss.

Proteins are also responsible for performing the contractile function. Due to the fact that myosin and actin protofibrils constantly perform sliding movements relative to each other, muscle fibers contract. But also single-celled organisms similar processes occur. The movement of bacterial flagella is also directly related to the sliding of microtubules, which are protein in nature.

The oxidation of organic substances releases large amounts of energy. But, as a rule, proteins are spent on energy needs very rarely. This occurs when all reserves are exhausted. Lipids and carbohydrates are best suited for this. Therefore, proteins can perform an energy function, but only under certain conditions.

Lipids

An organic substance is also a fat-like compound. Lipids belong to the simplest biological molecules. They are insoluble in water, but disintegrate in non-polar solutions such as gasoline, ether and chloroform. They are part of all living cells. Chemically, lipids are alcohols and carboxylic acids. The most famous of them are fats. In the body of animals and plants, these substances perform many important functions. Many lipids are used in medicine and industry.

Functions of lipids

These organic chemicals, together with proteins in cells, form biological membranes. But their main function is energy. When fat molecules are oxidized, a huge amount of energy is released. It goes to the formation of ATP in cells. Significant amounts of energy reserves can be stored in the body in the form of lipids. Sometimes there are even more of them than are needed for normal life activities. With pathological changes in metabolism, there are more “fat” cells. Although in fairness it should be noted that such excessive reserves are simply necessary for hibernating animals and plants. Many people believe that trees and shrubs feed on soil during the cold season. In reality, they use up the reserves of oils and fats that they made over the summer.

In the human and animal body, fats can also perform a protective function. They are deposited in the subcutaneous tissue and around organs such as the kidneys and intestines. Thus, they serve as good protection against mechanical damage, that is, impacts.

In addition, fats have low level thermal conductivity, which helps retain heat. This is very important, especially in cold climates. In marine animals, the subcutaneous fat layer also contributes to good buoyancy. But in birds, lipids also perform water-repellent and lubricating functions. The wax coats their feathers and makes them more flexible. Some types of plants have the same coating on the leaves.

Carbohydrates

The formula of an organic substance C n (H 2 O) m indicates that the compound belongs to the class of carbohydrates. The name of these molecules refers to the fact that they contain oxygen and hydrogen in the same amount as water. Besides these chemical elements, the compounds may contain, for example, nitrogen.

Carbohydrates in the cell are the main group of organic compounds. These are primary products. They are also the initial products of the synthesis in plants of other substances, for example, alcohols, organic acids and amino acids. Carbohydrates are also found in animal and fungal cells. They are also found among the main components of bacteria and protozoa. So, in animal cell their content is from 1 to 2%, and in plant matter their amount can reach 90%.

Today there are only three groups of carbohydrates:

Simple sugars (monosaccharides);

Oligosaccharides, consisting of several molecules of simple sugars connected in series;

Polysaccharides, they contain more than 10 molecules of monosaccharides and their derivatives.

Functions of carbohydrates

All organic substances in a cell perform specific functions. For example, glucose is the main energy source. It is broken down in cells all occurring during cellular respiration. Glycogen and starch constitute the main energy reserves, the former in animals and the latter in plants.

Carbohydrates also perform a structural function. Cellulose is the main component of plant cell walls. And in arthropods, chitin performs the same function. It is also found in the cells of higher fungi. If we take oligosaccharides as an example, they are part of the cytoplasmic membrane - in the form of glycolipids and glycoproteins. Glycocalyx is also often detected in cells. In synthesis nucleic acids pentoses are involved. When is included in DNA, and ribose is included in RNA. These components are also found in coenzymes, for example, FAD, NADP and NAD.

Carbohydrates are also able to perform a protective function in the body. In animals, the substance heparin actively prevents rapid blood clotting. It is formed during tissue damage and blocks the formation of blood clots in blood vessels. Heparin is found in large quantities in mast cells in granules.

Nucleic acids

Proteins, carbohydrates and lipids are not all known classes of organic substances. Chemistry also includes nucleic acids. These are phosphorus-containing biopolymers. They, located in the cell nucleus and cytoplasm of all living beings, ensure the transmission and storage of genetic data. These substances were discovered thanks to the biochemist F. Miescher, who studied salmon sperm. This was an "accidental" discovery. A little later, RNA and DNA were discovered in all plant and animal organisms. Nucleic acids were also isolated in the cells of fungi and bacteria, as well as viruses.

In total, two types of nucleic acids have been found in nature - ribonucleic acids (RNA) and deoxyribonucleic acids (DNA). The difference is clear from the name. deoxyribose is a five-carbon sugar. And ribose is found in the RNA molecule.

Organic chemistry deals with the study of nucleic acids. Topics for research are also dictated by medicine. DNA codes hide many genetic diseases that scientists have yet to discover.

Most organic thermal insulation materials are made in the form of slabs, usually large-sized, which simplifies and speeds up the work and helps reduce the cost of construction.

The main raw material for their production is wood in the form of waste (sawdust, shavings, slabs, lath) and other plant materials with a fibrous structure (reeds, straw, poorly decomposed high-moor peat, flax and hemp).

Wood is a porous material (porosity - 60-70%). In addition, wood chips and wood fibers in some thermal insulation products (fiberboards, particle boards) are arranged so that the heat flow in the structure is directed not along, but across the fibers, and this creates additional resistance to heat leakage. At the same time, shavings and fibers of wood or other plant materials create a kind of reinforcement frame in thermal insulation products. Finally, the use of wood and other plant waste for mass production of thermal insulation materials is economically beneficial and contributes to the solution environmental problem, i.e. helps reduce pollution environment.

To increase fire resistance, biostability and water resistance, fire retardants, antiseptics and water repellents are introduced into organic-based thermal insulation materials.

Fiberboards

Fiberboard is made from non-commercial wood, waste from the sawmill and woodworking industries, waste paper, straw stems, corn, cotton and some other plants.

In order to increase the strength, durability and fire resistance of wood fiber products, special additives are used: aqueous emulsions of synthetic resins, emulsions of paraffin, rosin, bitumen, antiseptics and fire retardants, as well as asbestos, alumina and gypsum.

Plant materials are crushed in various units in the presence of a large amount of water, which facilitates the separation of wood into individual fibers, and mixed with special additives. After this, the fluid fibrous mass is transferred to a casting machine consisting of an endless metal mesh and a vacuum installation. Here the mass is dehydrated, compacted and cut into individual slabs of a given size, which are then pressed and dried.

The density of wood-fiber insulating and insulating-finishing boards is 150-350 kg/m3, thermal conductivity is 0.046-0.093 W/(m K), bending strength is not less than 0.4-2.0 MPa.

The advantage of the slabs is their large size - length up to 3 m, width - up to 1.6 m, because this contributes to the industrialization of construction and installation work and the reduction of labor costs.

Insulating boards are used for heat and sound insulation of walls, ceilings, floors, partitions and interfloor ceilings, roof insulation (especially in wooden housing construction), acoustic finishing of special premises (radio studios, typing bureaus, concert halls).

Standard insulating boards are used for additional insulation of walls, ceilings and floors, as well as to increase the strength of wall frames. They can be used for interior coating of walls and ceilings before final finishing.

Wind barrier insulation boards are used to seal and strengthen the external walls, ceilings and roofs of buildings.

Insulating floor boards are used as a “floating” underlay under parquet and laminated floors. The slab levels the surface under the parquet, insulates the floor and significantly increases sound insulation.

Along with the advantages, fiberboards also have disadvantages. They have high water absorption (up to 18% per day), are characterized by significant hygroscopicity (up to 15% per day). normal conditions), when the environmental humidity changes, they change their size, and wood-destroying fungi can develop in them. Such boards are more flammable than ordinary wood.

The introduction of antiseptics and fire retardants into their composition makes it possible to reduce the rotting properties of fiberboards and increase their fire resistance.

Particle boards

These materials are products obtained by pressing wood chips with the addition of synthetic resins.

Like fibreboards, they have different densities. For thermal insulation, so-called light slabs are used, while for structural and finishing purposes - semi-heavy and heavy ones.

Light slabs are prepared from the same raw materials and using the same technology as semi-heavy and heavy slabs. The only difference is that in the manufacture of lightweight slabs the polymer consumption is lower (6-8%) and the pressure during pressing is lower than in the manufacture of structural and finishing ones.

Particle boards are produced by hot pressing of a mass containing about 90% organic fibrous raw materials (most often thin wood chips) and 8-12% synthetic resins.

Chipboards are produced in single-layer and multi-layer versions. For example, in a three-layer slab, the porous middle layer consists of relatively large chips, and the surface layer is made of thin flat chips of equal thickness.

Lightweight particle boards have a length of mm, a width of mm, and a thickness of 13 to 25 mm. Average density is 250-400 kg/m3. Their advantage over fibreboards is a simpler manufacturing technology; they are more durable, but have a slightly higher density. Other properties of particle boards and their areas of application are the same as those of wood fiber boards. They cost about the same as fiberboard.

This thermal insulation material is a type of lightweight concrete made from a rationally selected mixture of cement, organic aggregates, chemical additives and water. Organic fillers can be of different origins and with various shapes particles (crushed wood waste, reeds, hemp or flax, sunflower husks). Portland cement is often used as a binder, and other inorganic binders are less commonly used. The technology for manufacturing products from wood concrete is in many ways similar to that for the production of products from conventional concrete.

There are thermal insulating wood concrete (density up to 500 kg/m3) and structural thermal insulation (density up to 700 kg/m3). The thermal conductivity of wood concrete is 0.1-0.126 W/(m K). The material belongs to the category of materials that are difficult to attack by fungi and difficult to burn.

Arbolite is used for the construction of curtain and self-supporting walls and partitions, as well as as a thermal insulation material in walls, partitions and coverings of buildings for various purposes.

Fibrolite

This board material is usually made from special wood chips (wood wool) and an inorganic binder. Wood wool is obtained on special machines in the form of thin and narrow strips. Portland cement is used as a binder, less often magnesium binder.

Wood wool is first mineralized with a solution of calcium chloride, liquid glass or alumina sulphide, and then mixed with cement and water. The slabs are molded under a pressure of 0.5 MPa and sent to steaming chambers for hardening. The hardened slabs are dried to a moisture content of no more than 20%.

The slabs have a length of 240 and 300 cm, a width of 60 and 120 cm, a thickness of 3-15 cm. Based on their density, they are divided into grades F-300 (thermal-insulating fiberboard) and F-400, F-500 (thermal-insulating and structural fiberboard). Thermal conductivity - 0.08-0.1 W/(m K).

Fiberboard does not burn with an open flame, it is easy to process: it can be sawed, drilled and nails driven into it. Water absorption of cement fiberboard is no more than 35-45%. At a humidity above 35% it can be affected by house fungus, so it must be protected from moisture - in particular by plastering. The rough surface of the fiberboard promotes good adhesion to the plaster.

Magnesia fiberboard is made without special mineralization, since caustic magnesite is sealed aqueous solutions magnesium salts, which bind water-soluble substances contained in wood.

Peat insulation products

This thermal insulation material is obtained from peat by molding and heat treatment.

The raw material for the production of peat products is slightly decomposed moss - sphagnum (“white moss”) from the upper layers of peat bogs, which has retained its fibrous structure and is not used as fuel or agricultural fertilizer. About 50% of the world's peat reserves are located in Russia. Peat insulation products can be made in two ways - wet and dry.

Peat thermal insulation boards are characterized by a homogeneous fibrous structure of a finely porous structure with open communicating pores. The absolute porosity values of peat slabs range from 84-91%.

During the production of peat slabs, the structure of peat is slightly disturbed, and their average density is close to this indicator for raw peat. Peat slabs are produced with a density of 170-260 kg/m3. The bending strength of peat slabs is 0.3-0.5 MPa, which provides satisfactory conditions for their transportation and installation.

Water absorption of peat slabs is quite high. The highly porous structure of this type of TIM promotes capillary and hygroscopic wetting. Thus, the water absorption of ordinary slabs (by weight) in 24 hours is 190-180%, and of special waterproof ones - 50%.

The thermal conductivity of peat slabs in a dry state is low due to the mixed fine-porous structure and organic origin of the solid phase and amounts to 0.052-0.075 W/(m K).

Peat slabs are a flammable material. The ignition temperature is about 160°C, and the self-ignition temperature is about 300°C.

The maximum temperature for storage and operation of peat slabs is 100°C; however, it can be increased if flame retardants are added to their composition.

There are about 10 enterprises producing peat slabs in our country.

The dimensions of peat slabs are usually 1000x500x30 mm.

Depending on the purpose they can be:

- water resistant - B,

- · difficult to burn - Oh,

- · biostable - B,

- complex, having 2 or 3 of the above properties,

- · ordinary.

These thermal insulation products are used for thermal insulation of building envelopes of class 3 buildings and surfaces of industrial equipment with operating temperatures from - 60°C to 100°C.

Ecowool is a wood material made from waste paper. 80% of ecowool consists of newsprint, and 20% consists of non-volatile, health-safe additives that serve as antiseptics and fire retardants.

construction installation thermal insulation

Ecowool allows the building to “breathe”. It does not contain volatile chemicals hazardous to human health. Due to their antiseptic properties, boron and boric acid contained in ecowool protect ecowool and wooden structures in contact with it from rotting and fungal diseases. Boron compounds, which have insecticidal properties, prevent insects and rodents from growing in thermal insulation materials.

Ecowool belongs to the group of low-combustible materials. In the event of a fire, boron compounds in ecowool release water of crystallization: the insulation is moistened and retards the spread of fire. When ignited, ecowool does not emit any toxic gases.

The average density in structures is 35-65 kg/m3. Thermal conductivity - 0.041 W/(m K).

Construction felt

The characteristic features of felt materials are their fibrous structure, organic origin (synthetic fibers, animal fibers - wool - or plant origin).

The most effective from the point of view of thermal insulation qualities are waste padding polyester (clothing insulation), shevelin (linen tow), construction felt (panels made of rolled animal hair, mats made of polyethylene film, filled with waste synthetic fur, waste thread or felt made from synthetic fibers). The average density of such materials is 10-80 kg/m 3, thermal conductivity is 0.03-0.07 W/(m K).

To prevent moths from appearing, the felt is soaked in a 3% sodium fluoride solution and dried well. After mechanical processing, the felt takes the form of 2x2 m panels.

This material is flammable and is used mainly in wooden buildings: for insulating external doors, window frames, for thermal and sound insulation of walls and ceilings under plaster, insulating external corners in log houses, for window and door work.

Felts impregnated with clay mortar are used in furnace work for fire-fighting purposes.

This is a heat-insulating material in the form of slabs pressed from the stems of ordinary reeds.

Depending on the location of the stems, the slabs are transverse and longitudinal. Reed slabs are made from reeds or reeds harvested in autumn and winter. For the production of reed stone, mobile installations are used, equipped with high-performance presses, on which pressing is carried out, as well as wire stitching and trimming of slabs.

The density of reed stone, depending on the degree of pressing, is 175-250 kg/m3, thermal conductivity is 0.046-0.093 W/(m K), bending strength is 0.5-0.1 MPa.

Reed rots when wet, does not hold nails, can catch fire, and is susceptible to damage by rodents. These disadvantages can be reduced by impregnating the slabs with antiseptics or plastering.

They produce slabs with a length of mm, a width of mm, and a thickness of 30-100 mm. Density grades - 175, 200 and 250, bending strength - up to 0.5 MPa.

Reed is used to fill the walls of frame buildings, install partitions, insulate floors and coatings in low-rise construction, and for thermal insulation of small industrial premises in agricultural construction. This is one of the cheapest TIMs.

Cork boards

Cork insulation boards are made from the bark of the cork oak tree. This is a natural, ageless material. The cell that makes up the plug (there are approximately 40 million of them in 1 cm3) consists of minimum quantity solid and maximum quantity air.

Another feature of cork is the composition of the cell walls. Each wall consists of 5 layers: 2 layers of fiber, to which the air in the cell adheres, 2 dense and fatty layers; impervious to water, and a final woody layer, which gives rigidity to the cell and forms the final structure.

Cork materials are lightweight, resistant to compression and bending. In addition, this material does not shrink and rot. Cork is not exposed to alkalis. It cuts easily, guaranteeing clean and fast work. Cork is chemically inert and very durable. It never becomes moldy, and its physical properties practically do not change over time; it resists rodent attacks well. If this material is installed, for example, on the walls (ceiling) or on the floor in a work room, then it protects people from exposure to radiation. The plug does not conduct electric current and does not accumulate static electricity.

Materials made from cork do not burn, but only smolder (if there is a source open fire), after treatment with fire-resistant compounds they belong to the flammability class VT. When smoldering, cork does not release phenols and formaldehydes.

Thermal insulation material RAVE

The material is produced on the basis cellulose fibers and has excellent thermal insulation properties.

RIVE does not retain dampness and does not transfer it into the building. It does not evaporate and is not destroyed in rooms with high humidity and high temperatures (baths, saunas). The fibers do not emit harmful substances, do not pollute the air, and do not cause allergic reactions in the user. RAVE insulation is lightweight, it is easy to install and fasten into grooves and openings when assembling the structure.

In terms of its physical properties, such TIM is similar to wood, has a long service life, requiring no maintenance during the entire period of operation of the wooden structure, and most importantly, a house with RAVE insulation breathes. This material has excellent soundproofing and dustproofing properties, reduces background noise and keeps indoor air clean.

Thermal conductivity - 0.023 W/(m K).

Block insulation RAVE:

Thermal conductivity - 0.03 W/(m K).

Average density is about 25 kg/m3.

Resistor base materials

General information about aging

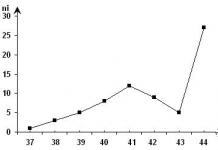

Aging is an irreversible change in the properties of materials under the influence of external and internal factors. According to statistics, on average for resistors, the change in contact resistance occurs by 1% per year.

The causes of aging are processes occurring under real operating conditions of EA such as: crystallization, electrochemical oxidation, electromigration, breaking of bonds in molecules, sorption processes, etc.

Sorption- absorption by material different substances from outside.

Absorption- absorption by volume of various substances.

Adsorption- absorption of various substances by the surface.

The most resistant to aging are resistors containing inorganic materials and wire RE. Among non-wire resistors, thin-film resistors, which, as a rule, do not contain organic additives, age more or less. And less resistant ones are composite ones with an organic dielectric - varnish.

The change in the resistance of the subsequent resistor depends on the ratio between the different components in terms of the rate of aging. For thin-film resistors, the resistance usually increases with aging; for thick-film resistors, aging is determined by the stability of the connecting dielectric materials included in the resistive paste (composition). The aging of wirewound resistors is determined by the resistance of resistive alloys to oxidative processes, except temperature, moisture and radiation. Aging is affected by atmospheric pressure greater than 3 atmospheres. At reduced pressure, due to a decrease in the electrical strength of air, it is necessary to reduce the operating voltage on the resistors in order to avoid overheating (due to deterioration of heat dissipation).

Organic and inorganic materials are used as dielectric bases of the resistor.

Advantages of organic material:

Organic material has the highest manufacturability. Manufacturability is a set of properties of a production object that ensures the minimum cost of the object (simple and cheap synthesis at a temperature< 1000 0 С). Органический материал является дешевым сырьем, возможность варьировать свойства, путем введения в массу добавок, как органических, так и неорганических.

Disadvantages of organic material:

Low heat resistance; for polyimide and fluoroplastic, the heat resistance is +250 0 C. Also, a disadvantage of organic materials is low thermal conductivity.

From organic materials, fiberglass laminate (fiberglass impregnated with epoxy resin with modifiers) is used as the base of resistors. Modifiers impart plasticity, vibration resistance and other intended properties to the organic mixture; heat resistance is +150 0 C.

Textolites (cotton fabric impregnated with phenol-formaldehyde resin with the necessary additives) are also used; the heat resistance is +105 0 C.

Getinaks is also used as organic materials - paper impregnated with phenolic resin, heat resistance is +100 0 C. The last two materials are used for resistors in micro-power circuits.

In the past, scientists divided all substances in nature into conditionally non-living and living, including the kingdom of animals and plants among the latter. Substances of the first group are called mineral. And those included in the second began to be called organic substances.

What does this mean? The class of organic substances is the most extensive among all chemical compounds known to modern scientists. The question of what substances are organic can be answered this way - these are chemical compounds that contain carbon.

Please note that not all carbon-containing compounds are organic. For example, corbides and carbonates, carbonic acid and cyanides, carbon oxides are not included in their number.

Why are there so many organic substances?

The answer to this question lies in the properties of carbon. This element is curious because it is capable of forming chains of its atoms. And at the same time, the carbon bond is very stable.

In addition, in organic compounds it exhibits high valence (IV), i.e. ability to form chemical bonds with other substances. And not only single, but also double and even triple (otherwise known as multiples). As the bond multiplicity increases, the chain of atoms becomes shorter and the stability of the bond increases.

Carbon is also endowed with the ability to form linear, flat and three-dimensional structures.

This is why organic substances in nature are so diverse. You can easily check this yourself: stand in front of a mirror and look carefully at your reflection. Each of us is a walking manual organic chemistry. Think about it: at least 30% of the mass of each of your cells is organic compounds. Proteins that built your body. Carbohydrates, which serve as “fuel” and a source of energy. Fats that store energy reserves. Hormones that control the functioning of organs and even your behavior. Enzymes that trigger chemical reactions inside you. And even the “source code”, the DNA chains, are all carbon-based organic compounds.

Composition of organic substances

As we said at the very beginning, the main building material for organic matter is carbon. And practically any element, when combined with carbon, can form organic compounds.

In nature, organic substances most often contain hydrogen, oxygen, nitrogen, sulfur and phosphorus.

Structure of organic substances

The diversity of organic substances on the planet and the diversity of their structure can be explained characteristic features carbon atoms.

You remember that carbon atoms are capable of forming very strong bonds with each other, connecting in chains. The result is stable molecules. The way in which the carbon atoms are connected into a chain (arranged in a zigzag) is one of the key features of its structure. Carbon can combine into both open chains and closed (cyclic) chains.

It is also important that the structure chemicals directly affects them chemical properties. Significant role The way atoms and groups of atoms in a molecule influence each other also plays a role.

Due to the structural features, the number of carbon compounds of the same type goes into tens and hundreds. For example, you can consider hydrogen compounds carbon: methane, ethane, propane, butane, etc.

For example, methane - CH 4. Such a compound of hydrogen with carbon under normal conditions remains in gaseous form. state of aggregation. When oxygen appears in the composition, a liquid is formed - methyl alcohol CH 3 OH.

Not only substances with different qualitative compositions (as in the example above) exhibit different properties, but substances of the same qualitative composition are also capable of this. An example would be different ability methane CH 4 and ethylene C 2 H 4 react with bromine and chlorine. Methane is capable of such reactions only when heated or under ultraviolet light. And ethylene reacts even without lighting or heating.

Let's consider this option: high-quality composition chemical compounds are the same, quantitative ones are different. Then the chemical properties of the compounds are different. As is the case with acetylene C 2 H 2 and benzene C 6 H 6.

Not the least role in this diversity is played by such properties of organic substances, “tied” to their structure, as isomerism and homology.

Imagine you have two seemingly identical substances—the same composition and the same molecular formula to describe them. But the structure of these substances is fundamentally different, from which follows the difference in chemical and physical properties. For example, molecular formula C 4 H 10 can be written two various substances: butane and isobutane.

It's about isomers– compounds that have the same composition and molecular weight. But the atoms in their molecules are arranged in different orders (branched and unbranched structure).

Regarding homology- this is a characteristic carbon chain, in which each next term can be obtained by adding one CH 2 group to the previous one. Every homologous series can be expressed in one general formula. And knowing the formula, it is easy to determine the composition of any of the members of the series. For example, homologs of methane are described by the formula C n H 2n+2.

As the “homologous difference” CH 2 increases, the bond between the atoms of the substance strengthens. Let's take the homologous series of methane: its first four members are gases (methane, ethane, propane, butane), the next six are liquids (pentane, hexane, heptane, octane, nonane, decane), and then follow substances in the solid state of aggregation (pentadecane, eicosane, etc.). And the stronger the bond between carbon atoms, the higher the molecular weight, boiling and melting points of substances.

What classes of organic substances exist?

Organic substances of biological origin include:

- proteins;

- carbohydrates;

- nucleic acids;

- lipids.

The first three points can also be called biological polymers.

A more detailed classification of organic chemicals covers substances not only of biological origin.

Hydrocarbons include:

- acyclic compounds:

- saturated hydrocarbons (alkanes);

- unsaturated hydrocarbons:

- alkenes;

- alkynes;

- alkadienes.

- cyclic connections:

- carbocyclic compounds:

- alicyclic;

- aromatic.

- heterocyclic compounds.

- carbocyclic compounds:

There are also other classes of organic compounds in which carbon combines with substances other than hydrogen:

- alcohols and phenols;

- aldehydes and ketones;

- carboxylic acids;

- esters;

- lipids;

- carbohydrates:

- monosaccharides;

- oligosaccharides;

- polysaccharides.

- mucopolysaccharides.

- amines;

- amino acids;

- proteins;

- nucleic acids.

Formulas of organic substances by class

Examples of organic substances

As you remember, in the human body various kinds of organic substances are the basis. These are our tissues and fluids, hormones and pigments, enzymes and ATP, and much more.

In the bodies of humans and animals, priority is given to proteins and fats (half of the dry mass of an animal cell is proteins). In plants (approximately 80% of the dry mass of the cell) - carbohydrates, primarily complex ones - polysaccharides. Including cellulose (without which there would be no paper), starch.

Let's talk about some of them in more detail.

For example, about carbohydrates. If it were possible to take and measure the masses of all organic substances on the planet, it would be carbohydrates that would win this competition.

They serve as a source of energy in the body and are building materials for cells, and also store substances. Plants use starch for this purpose, animals use glycogen.

In addition, carbohydrates are very diverse. For example, simple carbohydrates. The most common monosaccharides in nature are pentoses (including deoxyribose, which is part of DNA) and hexoses (glucose, which is familiar to you).

Like bricks, on a large construction site of nature, polysaccharides are built from thousands and thousands of monosaccharides. Without them, more precisely, without cellulose and starch, there would be no plants. And animals without glycogen, lactose and chitin would have a hard time.

Let's look carefully at squirrels. Nature is the greatest master of mosaics and puzzles: from just 20 amino acids, 5 million types of proteins are formed in the human body. Proteins also have many vital functions. For example, construction, regulation of processes in the body, blood clotting (there are separate proteins for this), movement, transport of certain substances in the body, they are also a source of energy, in the form of enzymes they act as a catalyst for reactions, and provide protection. Antibodies play an important role in protecting the body from negative external influences. And if a disorder occurs in the fine tuning of the body, antibodies, instead of destroying external enemies, can act as aggressors to the body’s own organs and tissues.

Proteins are also divided into simple (proteins) and complex (proteids). And they have properties unique to them: denaturation (destruction, which you have noticed more than once when hard-boiling an egg) and renaturation (this property has found wide application in the manufacture of antibiotics, food concentrates, etc.).

Let's not ignore lipids(fats). In our body they serve as a reserve source of energy. As solvents they help biochemical reactions occur. Participate in the construction of the body - for example, in the formation of cell membranes.

And a few more words about such interesting organic compounds as hormones. They participate in biochemical reactions and metabolism. So small, the hormones make men men (testosterone) and women women (estrogen). They make us happy or sad (thyroid hormones play an important role in mood swings, and endorphin gives a feeling of happiness). And they even determine whether we are “night owls” or “larks”. Are you ready to study late or prefer to get up early and do homework before school is decided not only by your daily routine, but also by certain adrenal hormones.

Conclusion

The world of organic matter is truly amazing. It is enough to delve into its study just a little to take your breath away from the feeling of kinship with all life on Earth. Two legs, four or roots instead of legs - we are all united by the magic of Mother Nature's chemical laboratory. It causes carbon atoms to join together in chains, react and create thousands of different chemical compounds.

Now you have a quick guide to organic chemistry. Of course, not all possible information is presented here. You may have to clarify some points yourself. But you can always use the route we have outlined for your own independent research.

You can also use the definition of organic matter, classification and general formulas of organic compounds given in the article and general information about them to prepare for chemistry lessons at school.

Tell us in the comments which section of chemistry (organic or inorganic) do you like best and why. Don't forget to share the article on social networks, so that your classmates can also use it.

Please let me know if you find any inaccuracies or errors in the article. We are all human and we all make mistakes sometimes.

website, when copying material in full or in part, a link to the source is required.

Organic thermal insulation materials and products are made from various plant materials: wood waste (shavings, sawdust, slabs, etc.), reeds, peat, flax tow, hemp, animal wool, and also based on polymers.

Many organic thermal insulation materials are subject to rapid decay, damage by various insects and are capable of fire, so they are pre-treated. Since the use of organic materials as backfill is ineffective due to inevitable sedimentation and the ability to rot, the latter are used as raw materials for the manufacture of slabs. In slabs, the base material is almost completely protected from moisture, and, consequently, from rotting; in addition, during the production of slabs, it is treated with antiseptics and fire retardants, which increase its durability.

Thermal insulation materials and products from organic raw materials. Among the wide variety of thermal insulation products made from organic raw materials, the most interesting are wood fiber boards, reed boards, fiberboard, peat boards, natural cork thermal insulation, as well as thermal insulating foam plastics.

Fiberboards used for heat and sound insulation of enclosing structures. They are made from loose wood or other plant fibers - non-commercial wood, wood processing industry waste, bonfire, straw, reeds, cotton. The most widespread are fiberboards obtained from wood waste, which are produced by hot pressing of a fibrous mass consisting of wood fibers, water, fillers, polymers and additives (antiseptics, fire retardants, water-repellent substances). To produce insulating boards, a casting machine is used, equipped with an endless metal mesh and a vacuum unit, where the mass is dewatered, compacted and cut into boards of the required sizes.

Photo. 11.6. Fiberboards

Fiberboards They produce five types: super-hard, hard, semi-hard, insulating-finishing and insulating. Insulating fibreboards have a length of 1200...3600 mm, a width of 1000...2800 mm and a thickness of 8...25 mm, a density of 250 kg/m 3, a bending strength of 1.2 MPa and a thermal conductivity of no more than 0.07 W/(m °C).

Along with insulating boards, insulating and finishing boards with the front surface painted or prepared for painting are used.

Reed slabs , or simply reed, is used for thermal insulation of enclosing structures of low-rise residential buildings, small industrial premises, and in agricultural construction.

Photo. 11.7. Reed slab

This is a thermal insulation material in the form of slabs pressed from reed stalks, which are then fastened with galvanized steel wire. For the production of reed slabs, mature annual stems with a diameter of 7...15 mm are used. Harvesting of stems should be done in the autumn-winter period. The slabs are pressed using special presses. Depending on the location of the reed stems, slabs with transverse (along the short side of the slab) and longitudinal arrangement of the stems are distinguished. The slabs are produced with a length of 2400x2800 mm, a width of 550... 1500 mm and a thickness of 30...100 mm, density grades D175, 200 and 250, with a bending strength of at least 0.18...0.5 MPa, thermal conductivity 0.06...0.09 W/ (m °C), humidity not more than 18% by weight.

Peat thermal insulation products manufactured in the form of slabs, shells and segments and used for thermal insulation of building envelopes of class III and surfaces of industrial equipment and pipelines at temperatures from - 60 to - 100 ° C.

Photo. 11.8. Peat slab

The raw material for their production is poorly decomposed high-moor peat, which has a fibrous structure, which facilitates the production of high-quality products from it by pressing. Plates are made with dimensions of 1000x500x30 mm by pressing in metal molds, followed by drying at a temperature of 120...150°C. Depending on the initial moisture content of the peat mass, there are two methods for making slabs: wet (humidity 90...95%) and dry (humidity about 35%). With the wet method, excess moisture during the pressing period is squeezed out of the peat mass through fine metal mesh. With the dry method, such meshes are not placed in molds. Based on density, peat insulating boards are divided into grades D 170 and 220 with a bending strength of 0.3 MPa, a dry thermal conductivity of 0.6 W/(m °C), and a humidity of no more than 15%.

Cement-fibrolite boards are a thermal insulation material made from a hardened mixture of Portland cement, water and wood wool.

Wood wool acts as a reinforcing frame in fiberboard. In appearance, thin wood shavings up to 500 mm long, 4...7 mm wide, 0.25...0.5 mm thick are prepared from non-commercial softwood on special wood-wool looms.

Photo. 11. 9. Cement fiberboard board

The wool is pre-dried, impregnated with mineralizers (calcium chloride, liquid glass) and mixed with cement paste using the wet method or with cement using the dry method (wood wool is sprinkled or pollinated with cement) in various types of mixing machines. At the same time, make sure that the wood wool is evenly covered with cement. Slabs are formed in two ways: by pressing and on conveyors, where fiberboard is formed in the form of a continuously moving belt, which is then cut into individual slabs (similar to vibratory rolling of reinforced concrete products). When pressing slabs, the specific pressure for heat-insulating fiberboard is taken to be up to 0.1 MPa, and for structural - up to 0.4 MPa. After molding, the slabs are steamed for 24 hours at a temperature of 30...35°C. Cement-fibrolite boards are produced in lengths of 2400...3000 mm, widths of 600...1200 mm, thicknesses of 30, 50, 75, 100 and 150 mm. Cement fiberboard is produced in three grades according to density: F300, 400 and 500, thermal conductivity 0.09...0.15 W/(m °C), water absorption no more than 20%. Fiberboard boards grade F300 is used as a heat-insulating material, grade F400 and 500 are used as structural and heat-insulating material for walls, partitions, ceilings and roofings of buildings.

Arbolite slabs They are also obtained by molding and heat treatment (or without it) of organic short-wave raw materials (crushed machine shavings or flails, chopped straw or reeds, sawdust, bonfires, etc.), treated with a mineralizer solution.

F  oto. 11.10. Arbolite slabs

oto. 11.10. Arbolite slabs

Chemical additives include calcium chloride, soluble glass, and alumina sulfate. The second component in the manufacture of wood concrete slabs is Portland cement. The slabs are molded in lengths and widths of 500, 600 and 700 mm, and thicknesses of 50, 60 and 70 mm. Dry density is 500 kg/m3, compressive strength is 0.3...3.5 MPa, bending strength is not less than 0.4 MPa, dry thermal conductivity is not more than 0.12 W/(m ° C), humidity not more than 20% by weight.

Cement particle boards domestic industry produces two brands: TsSP-1 and TsSP-2. The boards are made by pressing wood particles with cement binder and chemical additives.

DSP belongs to the group of refractory materials with increased biostability. They are produced in lengths of 3200...3600 mm, widths of 1200, 1250 and thicknesses of 8...10, 12...16, 18...28 and 30...40 mm with a polished and unpolished surface. DSP is produced with a density of 1100...1400 kg/m 3, humidity up to 9%, water absorption in 24 hours no more than 16% and thickness swelling no more than 2%.

Photo. 11.11. Cement particle boards

The slabs have enough high strength for bending, for slabs with a thickness of 8... 16 mm it is 9... 12 MPa, and for slabs with a thickness of 26... 40 mm - 7... 9 MPa, thermal conductivity - 0.26 W/(m °C ). DSP is used in wall panels, coating slabs, in suspended ceiling elements, ventilation ducts, in flooring, as window sill boards, cladding, cladding and other construction products.

Cork thermal insulation materials and products (plates, shells and segments) are used for thermal insulation of building envelopes, refrigerators and surfaces of refrigeration equipment, pipelines at temperatures of insulated surfaces from -150 to +70°C, for insulation of ship hulls. They are made by pressing crushed cork chips, which are obtained as waste from the production of stoppers from the bark of the cork oak or the so-called velvet tree.

Cork, due to its high porosity and the presence of resinous substances, is one of the best thermal insulation materials and is used for the production of slabs, shells and segments.

Photo. 11.12. Cork boards

Thermal insulating foams in the form of gas-filled plastics , as well as mineral wool and glass wool products are manufactured using a polymer binder.

Based on their physical structure, gas-filled plastics can be divided into three groups: cellular or foam (foam plastics), porous (poroplasts) and honeycomb (cellular plastics). Foams and honeycombs based on polymers are not only thermal insulation, but also structural materials. Thermal insulating materials made from plastics are divided according to the type of polymers used for their manufacture: into polystyrene - porous plastics based on suspension (beads) or emulsion polystyrene; polyvinyl chloride - porous plastics based on polyvinyl chloride; phenolic - porous plastics based on formaldehyde.

Porosization of polymers is based on the use of special substances that intensively release gases and swell the polymer crushed when heated. Such intumescent substances can be solid, liquid or gaseous.

Photo. 11.13. Foam boards

Solid foaming substances of greatest practical importance include carbonates, sodium and ammonium bicarbonates, which release CO 2 during decomposition. Liquid foaming agents include benzene, light benzene fractions, alcohol, etc. Gaseous foaming agents include air, nitrogen, carbon dioxide, and ammonia. To impart elasticity to porous plastics, plasticizers - phosphates, phthalates, etc. - are introduced into the polymers.

Porous and cellular plastics can be obtained in two ways: pressed and non-pressed. When producing porous plastics using the press method, finely ground polymer powder with a blowing agent and other additives is compressed under a pressure of 15...16 MPa, after which the sample taken (usually 2...2.5 kg) is foamed, resulting in a material with a cellular structure.

In the production of porous plastics using a non-press method, a polymer with additives of a blowing agent, hardener and; other components are heated in molds to the appropriate temperature. When heated, the polymer melts, the gas-forming agent decomposes, and the released gas foams the polymer. A material with a cellular structure is formed with small pores evenly distributed in it.

Plates, shells and segments made of porous plastics are used for thermal insulation of building envelopes and surfaces of industrial equipment and pipelines at temperatures up to 70°C.

Products made of porous plastics on suspension polystyrene according to dry density they are divided into grades D 25 and 35 with a bending strength of at least 0.1...0.2 MPa, thermal conductivity 0.04 W/(m °C), humidity not more than 2% by weight.

The same products on emulsion polystyrene have a density of grade D 50...200, a bending strength of at least 1.0...7.5 MPa, a thermal conductivity of no more than 0.04...0.05 W/(m °C), humidity not more than 1% by weight. Plates made of porous plastics; manufactured in lengths of 500...1000 mm, widths of 400...700 mm, thicknesses of 25...80 mm.

The same products on emulsion polystyrene have a density of grade D 50...200, a bending strength of at least 1.0...7.5 MPa, a thermal conductivity of no more than 0.04...0.05 W/(m °C), humidity not more than 1% by weight. Plates made of porous plastics; manufactured in lengths of 500...1000 mm, widths of 400...700 mm, thicknesses of 25...80 mm.

Photo. 11.14. Cellular plastic

The most common thermal insulation materials made from plastics are polystyrene foam, mipora, etc.

Polystyrene foam - excellent insulation in laminated panels, goes well with aluminum, asbestos cement and fiberglass. Widely used as an insulating material in the refrigeration industry, shipbuilding and carriage building for insulating walls, ceilings and roofs in construction. Polystyrene foam, made from beaded (suspension) polystyrene, is a material consisting of fine-cell spherical particles sintered together. There are voids of various sizes between the particles. The most valuable properties of polystyrene foam are its low density and low thermal conductivity. Polystyrene foam plastic is produced in the form of slabs or various shaped products; it is produced with a density of up to 60 kg/m 3, strength at 10% compression of up to 0.25 MPa and thermal conductivity of 0.03... 0.04 W/(m °C ). The most common slab size is 1200x1000x100(50) mm.

Polyurethane foam plastic used for thermal insulation of building envelopes and surfaces of industrial equipment and pipelines at temperatures up to 100°C.

It is obtained from polyester polymers by introducing pore-forming and other additives. Polyester polymers- this is a large group of artificial polymers obtained by condensation of polyhydric alcohols (glycol, glycerol, pentaerythritol, etc.) and mainly dibasic acids - phthalic, maleic, etc.

It is obtained from polyester polymers by introducing pore-forming and other additives. Polyester polymers- this is a large group of artificial polymers obtained by condensation of polyhydric alcohols (glycol, glycerol, pentaerythritol, etc.) and mainly dibasic acids - phthalic, maleic, etc.

Based on their density in the dry state, mats made of porous polyurethane are divided into grades D 35 and 50, their thermal conductivity in the dry state is 0.04 W/(m °C), humidity is not more than 1% by weight. Based on porous polyurethane, hard and soft boards with a density of 30...150 kg/m 3 and a thermal conductivity of 0.022...0.03 W/(m °C) are also produced. Porous polyurethane mats are made in the form of slabs 2000 mm long, 1000 mm wide, 30...60 mm thick.

Photo.11.15. Polyurethane foam plastic

M  Ipora

is a porous material obtained on the basis of urea-formaldehyde polymer. The raw materials for the production of mipora are urea-formaldehyde polymer and a 10% solution of sulfanaphthenic acids (Petrov’s contact), as well as fire retardant additives (20% concentration of ammonium phosphate solution).

Ipora

is a porous material obtained on the basis of urea-formaldehyde polymer. The raw materials for the production of mipora are urea-formaldehyde polymer and a 10% solution of sulfanaphthenic acids (Petrov’s contact), as well as fire retardant additives (20% concentration of ammonium phosphate solution).

Photo.11.16. Mipora

Miporu used for thermal insulation of building structures, industrial equipment and pipelines at temperatures up to 70°C.

To obtain mipora, an aqueous solution of urea-formaldehyde polymer and a foaming agent are loaded into an apparatus with a stirrer, which are vigorously mixed. The resulting foam is lowered into metal molds, which are sent to chambers where the mass hardens at a temperature of 18...22°C in 3...4 hours.

The resulting blocks are sent to a dryer for 60...80 hours at a temperature of 30...50°C. Mipore is produced in the form of blocks with a volume of at least 0.005 m 3, compressive strength 0.5...0.7 MPa, specific impact strength 400 MPa, water absorption 0.11% in 24 hours, thermal conductivity 0.03 W/(m °C).

Sovelite thermal insulation materials.

P  litas are made from dolomite lime and chrysolite asbestos. They withstand aging well and retain their thermal insulation properties for many years. They belong to the group of non-combustible substances, do not ignite and do not rot. The products do not contain corrosive agents.

litas are made from dolomite lime and chrysolite asbestos. They withstand aging well and retain their thermal insulation properties for many years. They belong to the group of non-combustible substances, do not ignite and do not rot. The products do not contain corrosive agents.

The products are environmentally friendly.

Photo.11.17. Sovelite slabs

Sovelite thermal insulation slabs are intended for thermal insulation of industrial equipment and pipelines, lining of steam boilers, thermal power plants, state district power plants, nuclear power plants, metallurgical and coke-and-gas industries, as well as large-diameter pipes at temperatures of insulated surfaces up to +600 o C. This slab is a universal material. They can also be used for domestic purposes (protection of heating elements, grills, heaters), etc.

Vermiculite (from Latin vermiculus - worm) - a mineral from the group of hydromicas with a layered structure. It is a lightweight, free-flowing, highly porous, odorless material. Large lamellar crystals (vermiculite slabs) are golden yellow or brown in color. When heated to a temperature of 900–1,000°C, vermiculite expands, exhibiting one of its most remarkable qualities: it increases in volume by 4.5–12 times, turning into expanded vermiculite. This phenomenon is explained by the fact that during calcination, molecular water in vermiculite flakes and packs turns into steam, under the pressure of which the mica leaves always move apart in one direction, perpendicular to the mica cleavage.

IN  When cooled, vermiculite expanded in this way retains its acquired volume with the thinnest gaskets of air instead of water vapor between the mica leaves, which gives the mineral many of its valuable properties, for example:

When cooled, vermiculite expanded in this way retains its acquired volume with the thinnest gaskets of air instead of water vapor between the mica leaves, which gives the mineral many of its valuable properties, for example:

durability. The indisputable advantage of vermiculite is that its shelf life and action are unlimited!

Photo.11.18. Vermiculite gravel

- lightness (0.065–0.130 g/cm 3 ), porosity and flowability . When backfilled during building insulation work, it fills all voids of small diameter and any irregular shape;

- heat resistance. Vermiculite melting point: 1350°C, operating temperature range: –260°C to +1200°C. The material is resistant to high temperatures and open fire. When exposed high temperatures does not emit gases, which is a definite advantage compared to other insulation materials;

- biological and chemical resistance . The material is odorless. It is not subject to decomposition and rotting under the influence of microorganisms, prevents the formation of mold, and the appearance of insects and rodents is excluded. Vermiculite does not interact with active chemicals in the environment.

- radiation protection. Vermiculite has the ability to reflect gamma radiation, as well as absorb radioactive substances - strontium-90, cesium-137, cobalt-58;

- environmental friendliness. Expanded vermiculite is an absolutely non-toxic, environmentally friendly and radiation-safe modern material, free of carcinogenic impurities;

- low hygroscopicity and high water absorption . Vermiculite has a high coefficient of moisture absorption (a volume of material weighing 100 g absorbs 400 ml of water) and when wet it slightly loses its mechanical strength. After drying, the expanded vermiculite restores its previous heat-sound-insulating and fire-fighting properties.

- high heat and sound insulation properties . Due to its porous structure, expanded vermiculite is an excellent heat and sound insulator (sound absorption coefficient at a frequency of 1000 Hz is in the range of 0.7–0.8), which makes it possible to successfully use it as bulk insulation when treating floors and roofs.

- efficiency. Insulation using vermiculite provides significant cost savings, since in terms of its energy-saving properties, expanded vermiculite is 7–10 times superior to traditional building materials such as concrete or brick.

All of the listed properties determine the unusually wide possibilities of its use as a multi-purpose raw material.

Expanded vermiculite is successfully used in more than 200 industrial applications around the world. Thanks to the above qualities, expanded vermiculite is widely used in construction, nuclear, food and chemical industries, agriculture, metallurgy, and shipbuilding.

The effect of using vermiculite as a fireproof bulk material with excellent heat and sound insulation qualities has already been appreciated in construction.

The use of vermiculite in construction has clear advantages over the use of traditional materials. Thanks to this material, it is possible not only to reduce the weight of individual structures and improve their quality, but also to reduce the consumption of valuable materials, reduce the cost of foundations and increase the usable area of buildings due to thin walls and partitions.

Expanded vermiculite has one of the lowest thermal conductivity values among thermal insulation materials – 0.04–0.062 W/m o C. A layer of backfill vermiculite, having a thickness of only 12 cm, in brickwork provides thermal insulation that meets modern requirements.

Loose-fill insulation of attics and floors.

A 5 cm thick layer of vermiculite covering the attic floors can reduce heat loss by 75%, and a 7.5 cm thick layer – by 85%. A 10 cm thick layer of vermiculite will increase thermal protection by 92%! Vermiculite is often placed in bags in attics, making it easy to remove the insulation if necessary.

Materials based on expanded vermiculite are effective in solving fire and fire protection problems. The high melting point (1350°C), significant reflectivity and high heat resistance of vermiculite have become decisive factors in the creation of fire-resistant vermiculite slabs and blocks. This is an environmentally friendly material, which, in addition to high fire resistance, has excellent sound absorption and thermal insulation properties.

The use of vermiculite at different stages of construction and in different qualities allows solving several problems at once. Protection of structures from fire, heat preservation, sound insulation both outside the building and inside between rooms and their improvement - in a word, today the range of use of vermiculite in construction is quite wide, and in the future, with the development of construction technologies, it will increase significantly.

Expanded perlite.

Perlite (obsidian hydroxide) is a rock of volcanic origin (essentially glass of volcanic origin). Chemical composition: SiO 2 -75.5; A1 2 O 3 -13.6; Fe 2 O 3 - 1.0; CaO -1.0; MgO - 0.3; Na 2 O - 3.8; K 2 O - 4.8. Distinctive feature What distinguishes perlite from other volcanic glasses is that when heated to a certain temperature within its softening range, it expands in volume from four to twenty times its original volume.

This swelling process occurs due to the presence of two to six percent bound water in natural perlite. When this rock is rapidly heated above 870°C, it bursts like<поп корна>, since bound water evaporates creates countless tiny bubbles in the softened vitrified particles. Because perlite is a form of natural glass, it is chemically inert and has a pH of approximately 7.

P  Erlite boards-PC products are used for thermal insulation of building structures of residential, public and industrial buildings and structures.

Erlite boards-PC products are used for thermal insulation of building structures of residential, public and industrial buildings and structures.

Perlite cement boards are intended for thermal insulation of structures of public and industrial buildings and structures, as well as for thermal insulation of industrial equipment at temperatures of the insulated surface up to 600°C (including DKVR and DE boilers).

Photo.11.19. Perlite board

Perlite cement slabs are packed in 8 slabs per package. B 1 cubic meter 80 slabs = 10 packs.

Physical and mechanical characteristics of the slabs: 1. Density, kg/m 3 320±25;

2. Bending strength, kgf/cm 2 2.5; 3. Thermal conductivity, W/m o C 0.070-0.120; 4. Temperature, °C up to 600; 5. Size, mm 500x500x50.

Expanded clay gravel. Expanded clay is a lightweight porous building material obtained by firing clay or shale. Expanded clay gravel has an oval shape. Expanded clay crushed stone differs only in that its grains are mainly cubic in shape with sharp edges and corners. It is also produced in the form of sand - expanded clay sand (see Chapter 3).

Shungizite gravel. Shungizite obtained by swelling of crushed shale shungite-containing rocks containing 1, 2 - 5% shungite substance. This is a special form of carbon, consisting of particles 0.2 microns in size, evenly distributed in a silicate mass.