Chromium

CHROMIUM-A; m.[from Greek chrōma - color, paint]

1. Chemical element (Cr), a hard metal of steel-gray color (used in the manufacture of hard alloys and for coating metal products).

2. Soft thin leather tanned with salts of this metal. Boots made of chrome.

3. A type of yellow paint obtained from chromates.

◁ Chrome (see).

chromium(lat. Chromium), chemical element of group VI periodic table. Named from the Greek. chrōma - color, paint (due to the bright color of the compounds). Bluish-silver metal; density 7.19 g/cm 3, t pl 1890°C. Does not oxidize in air. The main minerals are chrome spinels. Chromium is an essential component of stainless, acid-resistant, heat-resistant steels and a large number of other alloys (nichrome, chrome, stellite). Used for chrome plating. Chromium compounds are oxidizing agents, inorganic pigments, tanning agents.

CHROMIUMCHROME (Latin chromium, from the Greek chromium - color, color; chromium compounds are characterized by a wide color palette), Cr (read “chrome”), a chemical element with atomic number 24, atomic weight 51.9961. Located in group VIB in the 4th period of the periodic table of elements.

Natural chromium consists of a mixture of four stable nuclides: 50 Cr (mixture content 4.35%), 52 Cr (83.79%), 53 Cr (9.50%) and 54 Cr (2.36%). Configuration of two outer electronic layers 3s 2

r 6

d 5

4s 1

. Oxidation states range from 0 to +6, the most typical are +3 (the most stable) and +6 (valences III and VI).

Neutral atom radius 0.127 nm, ion radius (coordination number 6): Cr 2+ 0.073 nm, Cr 3+ 0.0615 nm, Cr 4+ 0.055 nm, Cr 5+ 0.049 nm and Cr 6+ 0.044 nm. The sequential ionization energies are 6.766, 16.49, 30.96, 49.1, 69.3 and 90.6 eV. Electron affinity 1.6 eV. Electronegativity according to Pauling (cm. PAULING Linus) 1,66.

History of discovery

In 1766, a mineral was discovered in the vicinity of Yekaterinburg, which was called “Siberian red lead,” PbCrO 4. Modern name- crocoite. In 1797, the French chemist L. N. Vauquelin (cm. VAUCLIN Louis Nicolas) isolated a new refractory metal from it (most likely Vauquelin obtained chromium carbide).

Being in nature

Contents in earth's crust 0.035% by weight. The chromium content in sea water is 2·10 -5 mg/l. Chromium is practically never found in free form. It is part of more than 40 different minerals (chromite FeCr 2 O 4, volkonskoite, uvarovite, vokelenite, etc.). Some meteorites contain chromium sulfide compounds.

Receipt

The industrial raw material for the production of chromium and chromium-based alloys is chromite. By reducing chromite melting with coke (reducing agent), iron ore and other components, ferrochrome with a chromium content of up to 80% (by weight) is obtained.

To obtain pure metal chromium, chromite is fired with soda and limestone in furnaces:

2Cr 2 O 3 + 2Na 2 CO 3 + 3O 2 = 4Na 2 CrO 4 + 4CO 2

The resulting sodium chromate Na 2 CrO 4 is leached with water, the solution is filtered, evaporated and treated with acid. In this case, Na 2 CrO 4 chromate transforms into Na 2 Cr 2 O 7 dichromate:

2Na 2 CrO 4 + H 2 SO 4 = Na 2 Cr 2 O 7 + Na 2 SO 4 + H 2 O

The resulting dichromate is reduced with sulfur:

Na 2 Cr 2 O 7 + 3S = Na 2 S + Cr 2 O 3 + 2SO 2,

The resulting pure chromium(III) oxide Cr 2 O 3 is subjected to aluminothermy:

Cr 2 O 3 + 2Al = Al 2 O 3 + 2Cr.

Silicon is also used:

2Cr 2 O 3 + 3Si = 3SiO 2 + 4Cr

To obtain high-purity chromium, technical chromium is electrochemically purified from impurities.

Physical and chemical properties

In its free form, it is a bluish-white metal with a cubic body-centered lattice, A= 0.28845 nm. At a temperature of 39°C it changes from a paramagnetic state to an antiferromagnetic state (Néel point). Melting point 1890°C, boiling point 2680°C. Density 7.19 kg/dm3.

Stable in air. At 300°C it burns to form green chromium (III) oxide Cr 2 O 3, which has amphoteric properties. By fusing Cr 2 O 3 with alkalis, chromites are obtained:

Cr 2 O 3 + 2NaOH = 2NaCrO 2 + H 2 O

Uncalcined chromium(III) oxide readily dissolves in alkaline solutions and in acids:

Cr 2 O 3 + 6HCl = 2CrCl 3 + 3H 2 O

The thermal decomposition of chromium carbonyl Cr(OH) 6 produces red basic chromium(II) oxide CrO. Brown or yellow hydroxide Cr(OH) 2 with weakly basic properties is precipitated when alkalis are added to solutions of chromium(II) salts.

Careful decomposition of chromium(VI) oxide CrO 3 under hydrothermal conditions produces chromium(IV) dioxide CrO 2, which is ferromagnetic and has metallic conductivity.

When concentrated sulfuric acid reacts with solutions of dichromates, red or violet-red crystals of chromium(VI) oxide CrO 3 are formed. A typically acidic oxide, when interacting with water it forms strong unstable chromic acids: chromic H 2 CrO 4 , dichromic H 2 Cr 2 O 7 and others.

Halides are known that correspond to different oxidation states of chromium. Chromium dihalides CrF 2, CrCl 2, CrBr 2 and CrI 2 and trihalides CrF 3, CrCl 3, CrBr 3 and CrI 3 were synthesized. However, unlike similar compounds of aluminum and iron, CrCl 3 trichloride and chromium tribromide CrBr 3 are non-volatile.

Among chromium tetrahalides, CrF 4 is stable, chromium tetrachloride CrCl 4 exists only in vapors. Chromium hexafluoride CrF 6 is known.

Chromium oxyhalides CrO 2 F 2 and CrO 2 Cl 2 were obtained and characterized.

Compounds of chromium with boron (borides Cr 2 B, CrB, Cr 3 B 4, CrB 2, CrB 4 and Cr 5 B 3), with carbon (carbides Cr 23 C 6, Cr 7 C 3 and Cr 3 C 2), were synthesized. with silicon (silicides Cr 3 Si, Cr 5 Si 3 and CrSi) and nitrogen (nitrides CrN and Cr 2 N).

Chromium(III) compounds are the most stable in solutions. In this oxidation state, chromium corresponds to both the cationic form and the anionic forms, for example, the 3- anion existing in an alkaline environment.

When chromium(III) compounds are oxidized in an alkaline environment, chromium(VI) compounds are formed:

2Na 3 + 3H 2 O 2 = 2Na 2 CrO 4 + 2NaOH + 8H 2 O

Cr (VI) corresponds to a number of acids that exist only in aqueous solutions: chromic H 2 CrO 4 , dichromic H 2 Cr 2 O 7 , trichromic H 3 Cr 3 O 10 and others that form salts - chromates, dichromates, trichromates, etc. .

Depending on the acidity of the environment, the anions of these acids easily convert into each other. For example, when a yellow solution of potassium chromate K 2 CrO 4 is acidified, orange potassium dichromate K 2 Cr 2 O 7 is formed:

2K 2 CrO 4 + 2HCl = K 2 Cr 2 O 7 + 2KCl + H 2 O

But if an alkali solution is added to the orange solution of K 2 Cr 2 O 7, the color turns yellow again because potassium chromate K 2 CrO 4 is formed again:

K 2 Cr 2 O 7 + 2KOH = 2K 2 CrO 4 + H 2 O

When a barium salt solution is added to a yellow solution containing chromate ions, a yellow precipitate of barium chromate BaCrO 4 precipitates:

Ba 2+ + CrO 4 2- = BaCrO 4

Chromium(III) compounds are strong oxidizing agents, for example:

K 2 Cr 2 O 7 + 14 HCl = 2CrCl 3 + 2KCl + 3Cl 2 + 7H 2 O

Application

The use of chromium is based on its heat resistance, hardness and corrosion resistance. They are used to produce alloys: stainless steel, nichrome, etc. A large amount of chromium is used for decorative corrosion-resistant coatings. Chromium compounds are fire-resistant materials. Chromium (III) oxide is a green paint pigment, also included in abrasive materials (GOI pastes). The color change upon reduction of chromium(VI) compounds is used to conduct a rapid analysis of the alcohol content in exhaled air.

The Cr 3+ cation is part of potassium chromium KCr(SO 4) 2 ·12H 2 O alum used in leather tanning.

Physiological action

Chromium is one of the biogenic elements and is constantly included in the tissues of plants and animals. In animals, chromium is involved in the metabolism of lipids, proteins (part of the enzyme trypsin), and carbohydrates. A decrease in chromium content in food and blood leads to a decrease in growth rate and an increase in cholesterol in the blood.

Chromium metal is virtually non-toxic, but chromium metal dust is irritating to lung tissue. Chromium(III) compounds cause dermatitis. Chromium(VI) compounds lead to various human diseases, including cancer. The maximum permissible concentration of chromium(VI) in atmospheric air is 0.0015 mg/m3.

Encyclopedic Dictionary. 2009 .

Synonyms:See what "chrome" is in other dictionaries:

chromium- chrome, and... Russian spelling dictionary

chromium- chrome/… Morphemic-spelling dictionary

- (from the Greek chroma color, paint). A grayish metal mined from chrome ore. Dictionary foreign words, included in the Russian language. Chudinov A.N., 1910. CHROME metal of grayish color; in its pure form x. not used; connections with... Dictionary of foreign words of the Russian language

CHROMIUM- see CHROME (Cr). Chromium compounds are found in wastewater many industrial enterprises producing chrome salts, acetylene, tannins, aniline, linoleum, paper, paints, pesticides, plastics, etc. Trivalent compounds are found in water... ... Fish Diseases: A Guide

CHROME, ah, husband. 1. Chemical element, hard light gray shiny metal. 2. Kind of yellow paint (special). | adj. chromium, aya, oh (to 1 value) and chrome, aya, oh. Chrome steel. Chrome ore. II. CHROME, ah, husband. A type of soft, thin leather. | adj... Dictionary Ozhegova

chromium- a, m. chrome m. novolat. chromium lat. chroma gr. dye. 1. Chemical element is a hard silvery metal used in the manufacture of hard alloys and for coating metal products. BAS 1. Metal discovered by Vauquelin... ... Historical Dictionary of Gallicisms of the Russian Language

CHROMIUM- CHROME, Chromium (from the Greek chroma paint), I symbol. SG, chem. element with at. weighing 52.01 (isotopes 50, 52, 53, 54); serial number 24, for! occupies a place in the even subgroup VI of group j of the periodic table. Compounds X. are often found in nature... Great Medical Encyclopedia

- (lat. Chromium) Cr, chemical element of group VI of Mendeleev’s periodic system, atomic number 24, atomic mass 51.9961. Name from Greek. chroma color, paint (due to the bright color of the Compound). Bluish silvery metal; density 7.19… … Big Encyclopedic Dictionary

CHROME 1, a, m. Ozhegov’s Explanatory Dictionary. S.I. Ozhegov, N.Yu. Shvedova. 1949 1992 … Ozhegov's Explanatory Dictionary

CHROME 2, a, m. A type of soft, thin leather. Ozhegov's explanatory dictionary. S.I. Ozhegov, N.Yu. Shvedova. 1949 1992 … Ozhegov's Explanatory Dictionary

Chrome is a refractory, very hard metal with extraordinary resistance to corrosion. These unique qualities have ensured that it is in such high demand in industry and construction.

The consumer is most often familiar not with chrome products, but with objects coated with a thin layer of metal. The dazzling mirror shine of such a coating is attractive in itself, but it also has a purely practical significance. Chrome is resistant to corrosion and can protect alloys and metals from rust.

And today we will answer questions about whether chromium is a metal or a non-metal, and if it is a metal, then what kind: black or non-ferrous, heavy or light. We will also tell you in what form chromium is found in nature, and what are the differences between chromium and other similar metals.

First, let's talk about what chromium looks like, what metals it contains, and what is special about such a substance. Chrome is a typical metal of a silvery-bluish color, heavy, superior in density, and also belongs to the category of refractory - its melting and boiling points are very high.

The element chromium is located in the secondary subgroup of group 6 in the 4th period. It is close in properties to molybdenum and tungsten, although it has noticeable differences. The latter most often manifest only highest degree oxidation, while chromium exhibits valency two, three, and six. This means that the element forms many different compounds.

It was the compounds that gave the name to the element itself - from the Greek paint, color. The fact is that its salts and oxides are painted in a wide variety of bright colors.

This video will tell you what chrome is:

Features and differences compared to other metals

When studying metal, two properties of the substance aroused the greatest interest: hardness and refractoriness. Chromium is one of the hardest metals - it ranks fifth and is inferior to uranium, iridium, tungsten and beryllium. However, this quality turned out to be unclaimed, since the metal had properties that were more important for industry.

Chromium melts at 1907 C. It is inferior to tungsten or molybdenum in this indicator, but is still classified as a refractory substance. True, its melting point is greatly influenced by impurities.

- Like many corrosion-resistant metals, chromium forms a thin and very dense oxide film in air. The latter covers the access of oxygen, nitrogen and moisture to the substance, which makes it invulnerable. The peculiarity is that it transfers this quality to its alloy with: in the presence of the element, the potential of the a-phase of iron increases and, as a result, the steel in air is also covered with a dense oxide film. This is the secret of stainless steel's durability.

- Being a refractory substance, the metal also increases the melting point of the alloy. Heat-resistant and heat-resistant steels necessarily include a proportion of chromium, sometimes very large - up to 60%. The addition of both and chromium has an even stronger effect.

- Chromium also forms alloys with its group mates – molybdenum and tungsten. They are used to coat parts where particularly high wear resistance under high temperature conditions is required.

The advantages and disadvantages of chromium are described below.

Chrome like metal (photo)

Advantages

Like any other substance, metal has its own advantages and disadvantages, and their combination determines its use.

- The undoubted advantage of the substance is its corrosion resistance and the ability to transfer this property to its alloys. Chrome stainless steels are of great importance because they solved a number of problems in the construction of ships, submarines, building frames, and so on.

- Corrosion resistance is ensured in another way - by covering the object with a thin layer of metal. The popularity of this method is very great; today there are at least a dozen methods of chrome plating under different conditions and to obtain different results.

- The chrome layer creates a bright mirror shine, so chrome plating is used not only to protect the alloy from corrosion, but also to obtain an aesthetic appearance. Moreover, modern chrome plating methods make it possible to create a coating on any material – not only on metal, but also on plastic and ceramics.

- Obtaining heat-resistant steel by adding chromium should also be considered an advantage of the substance. There are many areas where metal parts must operate at high temperatures, and iron itself does not have such resistance to stress at temperatures.

- Of all refractory substances, it is the most resistant to acids and bases.

- An advantage of the substance is its prevalence - 0.02% in the earth's crust, and a relatively simple method of extraction and production. Of course, it requires energy, but it cannot be compared with a complex one, for example.

Flaws

The disadvantages include qualities that do not allow full use of all the properties of chromium.

- First of all, this is a strong dependence of physical, and not just chemical properties, on impurities. Even the melting point of the metal was difficult to establish, since in the presence of an insignificant fraction of nitrogen or carbon, the indicator changed noticeably.

- Despite its higher electrical conductivity compared to chromium, chromium is used much less in electrical engineering and its cost is quite high. It is much more difficult to make anything from it: the high melting point and hardness significantly limit its use.

- Pure chromium is a malleable metal, but when it contains impurities it becomes very hard. To obtain at least a relatively ductile metal, it has to be subjected to additional processing, which, of course, increases manufacturing costs.

Metal structure

The chromium crystal has a body-centered cubic lattice, a = 0.28845 nm. Above a temperature of 1830 C, a modification with a face-centered cubic lattice can be obtained.

At a temperature of +38 C, a second-order phase transition with an increase in volume is recorded. In this case, the crystal lattice of the substance does not change, but its magnetic properties become completely different. Up to this temperature – the Néel point – chromium exhibits the properties of an antiferromagnet, that is, it is a substance that is almost impossible to magnetize. Above the Néel point, the metal becomes a typical paramagnetic, that is, it exhibits magnetic properties in the presence of a magnetic field.

Properties and characteristics

IN normal conditions the metal is quite inert - both due to the oxide film and simply by its nature. However, as the temperature increases, it reacts with simple substances, acids, and bases. Its compounds are very diverse and are used very widely. Physical characteristics metal, as mentioned, strongly depend on the amount of impurities. In practice, they deal with chromium with a purity of up to 99.5%. are:

IN normal conditions the metal is quite inert - both due to the oxide film and simply by its nature. However, as the temperature increases, it reacts with simple substances, acids, and bases. Its compounds are very diverse and are used very widely. Physical characteristics metal, as mentioned, strongly depend on the amount of impurities. In practice, they deal with chromium with a purity of up to 99.5%. are:

- melting point– 1907 C. This value serves as the boundary between refractory and ordinary substances;

- boiling point– 2671 C;

- Mohs hardness – 5;

- electrical conductivity– 9 · 106 1/(Ohm m). In this indicator, chromium is second only to silver and gold;

- resistivity–127 (Ohm mm2)/m;

- thermal conductivity substance is 93.7 W/(m K);

- specific heat–45 J/(g K).

The thermophysical characteristics of the substance are somewhat anomalous. At the Néel point, where the volume of the metal changes, the coefficient of its thermal expansion increases sharply and continues to grow with increasing temperature. Thermal conductivity also behaves anomalously - it drops at the Néel point and decreases when heated.

The element is one of the necessary: in the human body, chromium ions are participants in carbohydrate metabolism and the process of regulating insulin secretion. The daily dose is 50–200 mcg.

Chromium is non-toxic, although in the form of metal powder it can cause irritation to the mucous membranes. Its trivalent compounds are also relatively safe and are even used in the food and sports industries. But hexavalent ones are poisonous for humans and cause severe damage to the respiratory tract and gastrointestinal tract.

Today we will talk about the production and price of chromium metal per kg later.

This video will show you if the coating is chrome:

Production

In a large number of different minerals - often accompanies and. However, its content is not sufficient to be of industrial significance. Only rocks that contain at least 40% of the element are promising, so there are few minerals suitable for mining, mainly chromium iron ore or chromite.

The mineral is extracted by mine and quarry methods, depending on the depth of occurrence. And since the ore initially contains a large proportion of metal, it is almost never enriched, which, accordingly, simplifies and reduces the cost of the production process.

About 70% of the mined metal is used to alloy steel. Moreover, it is often used not in its pure form, but in the form of ferrochrome. The latter can be obtained directly in a shaft electric furnace or a blast furnace - this is how carbon ferrochrome is obtained. If a compound with a low carbon content is required, the aluminothermic method is used.

- This method produces both pure chromium and ferrochrome. To do this, a charge containing chromium iron ore, chromium oxide, sodium nitrate, etc. is loaded into the smelting shaft. The first portion, the ignition mixture, is set on fire, and the rest of the charge is loaded into the melt. At the end, flux - lime - is added to facilitate the extraction of chromium. Melting takes about 20 minutes. After some cooling, the shaft is tilted, the slag is released, returned to its original position and tilted again, now both chromium and slag are removed into the mold. After cooling, the resulting block is separated.

- Another method is also used - metallothermic smelting. It is carried out in an electric furnace in a rotating shaft. The charge here is divided into 3 parts, each with a different composition. This method allows you to extract more chromium, but, most importantly, reduces consumption.

- If it is necessary to obtain a chemically pure metal, they resort to laboratory method: crystals are planted by electrolysis of chromate solutions.

The cost of chromium metal per 1 kg fluctuates noticeably, since it depends on the volume of rolled metal produced - the main consumer of the element. In January 2017, 1 ton of metal was valued at $7,655.

Application

Categories

So, . The main consumer of chromium is ferrous metallurgy. This is due to the ability of the metal to transfer such properties as corrosion resistance and hardness to its alloys. Moreover, it has an effect when added in very small quantities.

All chromium and iron alloys are divided into 2 categories:

- low alloy– with a chromium share of up to 1.6%. In this case, chromium adds strength and hardness to the steel. If ordinary steel has a tensile strength of 400–580 MPa, then the same grade of steel with the addition of 1% of the substance will demonstrate a tensile strength of 1000 MPa;

- highly alloyed– contain more than 12% chromium. Here the metal provides the alloy with the same resistance to corrosion that it itself has. All stainless steels are called chrome because it is this element that provides this quality.

Low-alloy steels are classified as structural: they are used to make numerous machine parts - shafts, gears, pushers, and so on. The scope of use of stainless steel is huge: metal parts of turbines, ship and submarine hulls, combustion chambers, fasteners of any kind, pipes, channels, angles, sheet steel and so on.

In addition, chromium increases the alloy’s resistance to temperature: with a substance content of 30 to 66%, products made of heat-resistant steel can perform their functions when heated to 1200 C. This is a material for piston engine valves, for fasteners, for turbine parts and other things.

If 70% of chromium is used for the needs of metallurgy, then the remaining almost 30% is used for chrome plating. The essence of the process comes down to applying a thin layer of chromium to the surface of a metal object. A variety of methods are used for this, many are available to home craftsmen.

Chrome plating

Chrome plating can be divided into 2 categories:

Chrome plating can be divided into 2 categories:

- functional– its purpose is to prevent corrosion of the product. The layer thickness here is greater, so the chrome plating process takes longer - sometimes up to 24 hours. In addition to preventing rust, the chrome layer significantly increases the wear resistance of the part;

- decorative– chrome creates a mirror-shiny surface. Car enthusiasts and motorcycle racers rarely turn down the opportunity to decorate their car with chrome parts. The decorative layer of the coating is much thinner - up to 0.0005 mm.

Chrome plating is actively used in modern construction and in the manufacture of furniture. Fittings with a mirror finish, bathroom and kitchen accessories, kitchen utensils, furniture parts - products with a chrome finish are extremely popular. And since thanks modern method chrome plating, the coating can be created on literally any object; somewhat atypical methods of application have also appeared. For example, chrome-plated plumbing cannot be classified as a trivial solution.

Chrome is a metal with very unusual properties, and its qualities are in demand in industry. For the most part, its alloys and compounds are of interest, which only increases the importance of the metal for the national economy.

The video below will tell you about removing chrome from metal:

The discovery of chromium dates back to a period of rapid development of chemical and analytical studies of salts and minerals. In Russia, chemists took a special interest in the analysis of minerals found in Siberia and almost unknown in Western Europe. One of these minerals was Siberian red lead ore (crocoite), described by Lomonosov. The mineral was examined, but nothing but oxides of lead, iron and aluminum were found in it. However, in 1797, Vaukelin, boiling a finely ground sample of the mineral with potash and precipitating lead carbonate, obtained a solution colored orange-red. From this solution he crystallized a ruby-red salt, from which the oxide and free metal, different from all known metals, were isolated. Vauquelin called him Chromium ( Chrome ) from the Greek word- coloring, color; True, what was meant here was not the property of the metal, but its brightly colored salts.

Being in nature.

The most important chromium ore of practical importance is chromite, the approximate composition of which corresponds to the formula FeCrO 4.

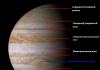

It is found in Asia Minor, the Urals, North America, in southern Africa. The above-mentioned mineral crocoite – PbCrO 4 – is also of technical importance. Chromium oxide (3) and some of its other compounds are also found in nature. In the earth's crust, the chromium content in terms of metal is 0.03%. Chromium has been found in the Sun, stars, and meteorites.

Chrome is a white, hard and brittle metal, extremely chemically resistant to acids and alkalis. In air it oxidizes and has a thin transparent film of oxide on the surface. Chromium has a density of 7.1 g/cm3, its melting point is +1875 0 C.

Receipt.

When chromium iron ore is heated strongly with coal, chromium and iron are reduced:

FeO * Cr 2 O 3 + 4C = 2Cr + Fe + 4CO

As a result of this reaction, an alloy of chromium with iron is formed, which differs high strength. To obtain pure chromium, it is reduced from chromium(3) oxide with aluminum:

Cr 2 O 3 + 2Al = Al 2 O 3 + 2Cr

In this process, two oxides are usually used - Cr 2 O 3 and CrO 3

Chemical properties.

Thanks to the thin protective film of oxide covering the surface of chrome, it is highly resistant to aggressive acids and alkalis. Chromium does not react with concentrated nitric and sulfuric acids, as well as with phosphoric acid. Chromium reacts with alkalis at t = 600-700 o C. However, chromium interacts with dilute sulfuric and hydrochloric acids, displacing hydrogen:

2Cr + 3H 2 SO 4 = Cr 2 (SO 4) 3 + 3H 2

2Cr + 6HCl = 2CrCl3 + 3H2

At high temperatures, chromium burns in oxygen, forming oxide(III).

Hot chromium reacts with water vapor:

2Cr + 3H 2 O = Cr 2 O 3 + 3H 2

At high temperatures, chromium also reacts with halogens, halogen with hydrogen, sulfur, nitrogen, phosphorus, carbon, silicon, boron, for example:

Cr + 2HF = CrF 2 + H 2

2Cr + N2 = 2CrN

2Cr + 3S = Cr 2 S 3

Cr + Si = CrSi

The above physical and chemical properties of chromium have found their application in various fields of science and technology. For example, chromium and its alloys are used to produce high-strength, corrosion-resistant coatings in mechanical engineering. Alloys in the form of ferrochrome are used as metal-cutting tools. Chrome alloys have found application in medical technology and in the manufacture of chemical technological equipment.

Position of chromium in the periodic table chemical elements:

Chromium heads the secondary subgroup of group VI of the periodic table of elements. His electronic formula next:

24 Cr IS 2 2S 2 2P 6 3S 2 3P 6 3d 5 4S 1

In filling the orbitals with electrons in the chromium atom, the pattern according to which the 4S orbital should first be filled to the 4S 2 state is violated. However, due to the fact that the 3d orbital occupies a more favorable energy position in the chromium atom, it is filled to the value 4d 5 . This phenomenon is observed in atoms of some other elements of secondary subgroups. Chromium can exhibit oxidation states from +1 to +6. The most stable are chromium compounds with oxidation states +2, +3, +6.

Compounds of divalent chromium.

Chromium (II) oxide CrO is a pyrophoric black powder (pyrophoricity - the ability to ignite in air in a finely crushed state). CrO dissolves in dilute hydrochloric acid:

CrO + 2HCl = CrCl 2 + H 2 O

In air, when heated above 100 0 C, CrO turns into Cr 2 O 3.

Divalent chromium salts are formed when chromium metal is dissolved in acids. These reactions take place in an atmosphere of low-active gas (for example H 2), because in the presence of air, oxidation of Cr(II) to Cr(III) easily occurs.

Chromium hydroxide is obtained in the form of a yellow precipitate by the action of an alkali solution on chromium (II) chloride:

CrCl 2 + 2NaOH = Cr(OH) 2 + 2NaCl

Cr(OH) 2 has basic properties and is a reducing agent. The hydrated Cr2+ ion is pale blue. An aqueous solution of CrCl 2 is blue in color. In air in aqueous solutions, Cr(II) compounds transform into Cr(III) compounds. This is especially pronounced in Cr(II) hydroxide:

4Cr(OH) 2 + 2H 2 O + O 2 = 4Cr(OH) 3

Trivalent chromium compounds.

Chromium (III) oxide Cr 2 O 3 is a refractory green powder. Its hardness is close to corundum. In the laboratory it can be obtained by heating ammonium dichromate:

(NH 4) 2 Cr 2 O 7 = Cr 2 O 3 + N 2 + 4H 2

Cr 2 O 3 is an amphoteric oxide, when fused with alkalis it forms chromites: Cr 2 O 3 + 2NaOH = 2NaCrO 2 + H 2 O

Chromium hydroxide is also an amphoteric compound:

Cr(OH) 3 + HCl = CrCl 3 + 3H 2 O

Cr(OH) 3 + NaOH = NaCrO 2 + 2H 2 O

Anhydrous CrCl 3 has the appearance of dark purple leaves, is completely insoluble in cold water, and dissolves very slowly when boiled. Anhydrous chromium (III) sulfate Cr 2 (SO 4) 3 is pink in color and is also poorly soluble in water. In the presence of reducing agents, it forms purple chromium sulfate Cr 2 (SO 4) 3 *18H 2 O. Green chromium sulfate hydrates containing less water are also known. Chromium alum KCr(SO 4) 2 *12H 2 O crystallizes from solutions containing violet chromium sulfate and potassium sulfate. A solution of chrome alum turns green when heated due to the formation of sulfates.

Reactions with chromium and its compounds

Almost all chromium compounds and their solutions are intensely colored. Having a colorless solution or a white precipitate, we can with a high degree of probability conclude that chromium is absent.

- Let us strongly heat in the flame of a burner on a porcelain cup such an amount of potassium dichromate that will fit on the tip of a knife. The salt will not release water of crystallization, but will melt at a temperature of about 400 0 C to form a dark liquid. Let's heat it for a few more minutes over high heat. After cooling, a green precipitate forms on the shard. Let's dissolve part of it in water (it turns yellow), and leave the other part on the shard. The salt decomposed when heated, resulting in the formation of soluble yellow potassium chromate K 2 CrO 4 and green Cr 2 O 3.

- Dissolve 3g of powdered potassium bichromate in 50ml of water. Add a little potassium carbonate to one part. It will dissolve with the release of CO 2, and the color of the solution will turn light yellow. Chromate is formed from potassium dichromate. If you now add a 50% sulfuric acid solution in portions, the red-yellow color of the dichromate will appear again.

- Pour 5 ml into a test tube. potassium bichromate solution, boil with 3 ml of concentrated hydrochloric acid under pressure. Yellow-green toxic chlorine gas is released from the solution because the chromate will oxidize HCl to Cl 2 and H 2 O. The chromate itself will turn into green trivalent chromium chloride. It can be isolated by evaporating the solution, and then, fused with soda and saltpeter, converted into chromate.

- When a solution of lead nitrate is added, yellow lead chromate precipitates; When interacting with a solution of silver nitrate, a red-brown precipitate of silver chromate is formed.

- Add hydrogen peroxide to the potassium dichromate solution and acidify the solution with sulfuric acid. The solution acquires a deep blue color due to the formation of chromium peroxide. When shaken with a certain amount of ether, the peroxide will go into the organic solvent and color it blue. This reaction is specific for chromium and is very sensitive. It can be used to detect chromium in metals and alloys. First of all, you need to dissolve the metal. During prolonged boiling with 30% sulfuric acid (you can also add hydrochloric acid), chromium and many steels are partially dissolved. The resulting solution contains chromium (III) sulfate. To be able to carry out a detection reaction, we first neutralize it with caustic soda. Gray-green chromium(III) hydroxide precipitates, which dissolves in excess NaOH to form green sodium chromite. Filter the solution and add 30% hydrogen peroxide. When heated, the solution will turn yellow as chromite oxidizes to chromate. Acidification will cause the solution to appear blue. The colored compound can be extracted by shaking with ether.

Analytical reactions for chromium ions.

- Add a 2M NaOH solution to 3-4 drops of chromium chloride solution CrCl 3 until the initial precipitate dissolves. Note the color of the sodium chromite formed. Heat the resulting solution in a water bath. What happens?

- To 2-3 drops of CrCl 3 solution, add an equal volume of 8 M NaOH solution and 3-4 drops of 3% H 2 O 2 solution. Heat the reaction mixture in a water bath. What happens? What precipitate is formed if the resulting colored solution is neutralized, CH 3 COOH is added to it, and then Pb(NO 3) 2 is added?

- Pour 4-5 drops of solutions of chromium sulfate Cr 2 (SO 4) 3, IMH 2 SO 4 and KMnO 4 into the test tube. Heat the reaction mixture for several minutes in a water bath. Note the change in color of the solution. What caused it?

- To 3-4 drops of K 2 Cr 2 O 7 solution acidified with nitric acid, add 2-3 drops of H 2 O 2 solution and mix. The emerging blue color of the solution is due to the appearance of perchromic acid H 2 CrO 6:

Cr 2 O 7 2- + 4H 2 O 2 + 2H + = 2H 2 CrO 6 + 3H 2 O

Pay attention to the rapid decomposition of H 2 CrO 6:

2H 2 CrO 6 + 8H+ = 2Cr 3+ + 3O 2 + 6H 2 O

blue green color

Perchromic acid is much more stable in organic solvents.

- To 3-4 drops of K 2 Cr 2 O 7 solution acidified with nitric acid, add 5 drops of isoamyl alcohol, 2-3 drops of H 2 O 2 solution and shake the reaction mixture. The layer of organic solvent that floats to the top is colored bright blue. The color fades very slowly. Compare the stability of H 2 CrO 6 in organic and aqueous phases.

- When CrO 4 2- interacts with Ba 2+ ions, a yellow precipitate of barium chromate BaCrO 4 precipitates.

- Silver nitrate forms a brick-red silver chromate precipitate with CrO 4 2 ions.

- Take three test tubes. Place 5-6 drops of K 2 Cr 2 O 7 solution into one of them, the same volume of K 2 CrO 4 solution into the second, and three drops of both solutions into the third. Then add three drops of potassium iodide solution to each test tube. Explain your result. Acidify the solution in the second test tube. What happens? Why?

Entertaining experiments with chromium compounds

- A mixture of CuSO 4 and K 2 Cr 2 O 7 turns green when alkali is added, and turns yellow in the presence of acid. By heating 2 mg of glycerol with a small amount of (NH 4) 2 Cr 2 O 7 and then adding alcohol, after filtration a bright green solution is obtained, which turns yellow when acid is added, and turns green in a neutral or alkaline environment.

- Place a “ruby mixture” in the center of a tin can with thermite - carefully ground and placed in aluminum foil Al 2 O 3 (4.75 g) with the addition of Cr 2 O 3 (0.25 g). To prevent the jar from cooling down longer, it is necessary to bury it under the top edge in sand, and after the thermite is set on fire and the reaction begins, cover it with an iron sheet and cover it with sand. Dig out the jar in a day. The result is a red ruby powder.

- 10 g of potassium dichromate is ground with 5 g of sodium or potassium nitrate and 10 g of sugar. The mixture is moistened and mixed with collodion. If the powder is compressed in a glass tube, and then the stick is pushed out and set on fire at the end, a “snake” will begin to crawl out, first black, and after cooling - green. A stick with a diameter of 4 mm burns at a speed of about 2 mm per second and extends 10 times.

- If you mix solutions of copper sulfate and potassium dichromate and add a little ammonia solution, an amorphous brown precipitate with the composition 4СuCrO 4 * 3NH 3 * 5H 2 O will form, which dissolves in hydrochloric acid to form a yellow solution, and in excess of ammonia a green solution is obtained. If you further add alcohol to this solution, a green precipitate will form, which after filtration becomes blue, and after drying, blue-violet with red sparkles, clearly visible in strong light.

- The chromium oxide remaining after the “volcano” or “pharaoh’s snakes” experiments can be regenerated. To do this, you need to fuse 8 g of Cr 2 O 3 and 2 g of Na 2 CO 3 and 2.5 g of KNO 3 and treat the cooled alloy with boiling water. The result is a soluble chromate, which can be converted into other Cr(II) and Cr(VI) compounds, including the original ammonium dichromate.

Examples of redox transitions involving chromium and its compounds

1. Cr 2 O 7 2- -- Cr 2 O 3 -- CrO 2 - -- CrO 4 2- -- Cr 2 O 7 2-

a) (NH 4) 2 Cr 2 O 7 = Cr 2 O 3 + N 2 + 4H 2 O  b) Cr 2 O 3 + 2NaOH = 2NaCrO 2 + H 2 O

b) Cr 2 O 3 + 2NaOH = 2NaCrO 2 + H 2 O

c) 2NaCrO 2 + 3Br 2 + 8NaOH = 6NaBr + 2Na 2 CrO 4 + 4H 2 O

d) 2Na 2 CrO 4 + 2HCl = Na 2 Cr 2 O 7 + 2NaCl + H 2 O

2. Cr(OH) 2 -- Cr(OH) 3 -- CrCl 3 -- Cr 2 O 7 2- -- CrO 4 2-

a) 2Cr(OH) 2 + 1/2O 2 + H 2 O = 2Cr(OH) 3

b) Cr(OH) 3 + 3HCl = CrCl 3 + 3H 2 O

c) 2CrCl 3 + 2KMnO 4 + 3H 2 O = K 2 Cr 2 O 7 + 2Mn(OH) 2 + 6HCl

d) K 2 Cr 2 O 7 + 2KOH = 2K 2 CrO 4 + H 2 O

3. CrO -- Cr(OH) 2 -- Cr(OH) 3 -- Cr(NO 3) 3 -- Cr 2 O 3 -- CrO - 2

Cr 2+

a) CrO + 2HCl = CrCl 2 + H 2 O

b) CrO + H 2 O = Cr(OH) 2

c) Cr(OH) 2 + 1/2O 2 + H 2 O = 2Cr(OH) 3

d) Cr(OH) 3 + 3HNO 3 = Cr(NO 3) 3 + 3H 2 O

e) 4Сr(NO 3) 3 = 2Cr 2 O 3 + 12NO 2 + O 2

e) Cr 2 O 3 + 2 NaOH = 2NaCrO 2 + H 2 O

Chromium element as an artist

Chemists quite often turned to the problem of creating artificial pigments for painting. In the 18th-19th centuries, the technology for producing many painting materials was developed. Louis Nicolas Vauquelin in 1797, who discovered the previously unknown element chromium in Siberian red ore, prepared a new, remarkably stable paint - chrome green. Its chromophore is hydrous chromium(III) oxide. It began to be produced under the name “emerald green” in 1837. Later, L. Vauquelin proposed several new paints: barite, zinc and chrome yellow. Over time, they were replaced by more persistent yellow and orange cadmium-based pigments.

Green chrome is the most durable and light-resistant paint that is not susceptible to atmospheric gases. Chromium green ground in oil has great covering power and is capable of drying quickly, which is why it has been used since the 19th century. it is widely used in painting. It is of great importance in porcelain painting. The fact is that porcelain products can be decorated with both underglaze and overglaze painting. In the first case, paints are applied to the surface of only a lightly fired product, which is then covered with a layer of glaze. This is followed by the main, high-temperature firing: to sinter the porcelain mass and melt the glaze, the products are heated to 1350 - 1450 0 C. Very few paints can withstand such a high temperature without chemical changes, and in the old days there were only two of them - cobalt and chrome. Black cobalt oxide applied to the surface of a porcelain product fuses with the glaze during firing, chemically interacting with it. As a result, bright blue cobalt silicates are formed. Everyone knows this cobalt-decorated blue porcelain tableware well. Chromium (III) oxide does not react chemically with the components of the glaze and simply lies between the porcelain shards and the transparent glaze as a “blind” layer.

In addition to chrome green, artists use paints obtained from volkonskoite. This mineral from the group of montmorillonites (a clay mineral of the subclass of complex silicates Na(Mo,Al), Si 4 O 10 (OH) 2 was discovered in 1830 by the Russian mineralogist Kemmerer and named in honor of M.N. Volkonskaya, the daughter of the hero of the Battle of Borodino, General N. .N. Raevsky, wife of the Decembrist S.G. Volkonsky. Volkonskoite is a clay containing up to 24% chromium oxide, as well as oxides of aluminum and iron (III). determines its varied color - from the color of winter darkened fir to the bright green color of a marsh frog.

Pablo Picasso turned to the geologists of our country with a request to study the reserves of volkonskoite, which produces paint of a uniquely fresh tone. Currently, a method for producing artificial volkonskoite has been developed. It is interesting to note that, according to modern research, Russian icon painters used paints from this material back in the Middle Ages, long before its “official” discovery. Guinier greens (created in 1837), the chromoform of which is chromium oxide hydrate Cr 2 O 3 * (2-3) H 2 O, where part of the water is chemically bound and part is adsorbed, was also famously popular among artists. This pigment gives the paint an emerald hue.

website, when copying material in full or in part, a link to the source is required.

Cr2+. The charge concentration of the divalent chromium cation corresponds to the charge concentration of the magnesium cation and the divalent iron cation, therefore a number of properties, especially the acid-base behavior of these cations, are close. Moreover, as already mentioned, Cr 2+ is a strong reducing agent, so the following reactions take place in the solution: 2CrCl 2 + 2HCl = 2CrCl 3 + H 2 4CrCl 2 + 4HCl + O 2 = 4CrCl 3 + 2H 2 O. Quite slowly, but even oxidation with water occurs: 2CrSO 4 + 2H 2 O = 2Cr(OH)SO 4 + H 2. The oxidation of divalent chromium occurs even more easily than the oxidation of divalent iron; salts also undergo cation hydrolysis to a moderate extent (i.e., the first step is dominant).

CrO is a basic oxide, black in color, pyrophoric. At 700 o C it disproportions: 3CrO = Cr 2 O 3 + Cr. It can be obtained by thermal decomposition of the corresponding hydroxide in the absence of oxygen.

Cr(OH) 2 – insoluble base yellow color. Reacts with acids, while oxidizing acids simultaneously with acid-base interaction oxidize divalent chromium; under certain conditions, this also happens with non-oxidizing acids (oxidizing agent - H +). When produced by an exchange reaction, chromium (II) hydroxide quickly turns green due to oxidation:

4Cr(OH) 2 + O 2 = 4CrO(OH) + 2H 2 O.

Oxidation is also accompanied by the decomposition of chromium (II) hydroxide in the presence of oxygen: 4Cr(OH) 2 = 2Cr 2 O 3 + 4H 2 O.

Cr3+. Chromium(III) compounds chemical properties similar to compounds of aluminum and iron (III). Oxide and hydroxide are amphoteric. Salts of weak unstable and insoluble acids (H 2 CO 3, H 2 SO 3, H 2 S, H 2 SiO 3) undergo irreversible hydrolysis:

2CrCl 3 + 3K 2 S + 6H 2 O = 2Cr(OH) 3 ↓ + 3H 2 S + 6KCl; Cr 2 S 3 + 6H 2 O = 2Cr(OH) 3 ↓ + 3H 2 S.

But the chromium (III) cation is not a very strong oxidizing agent, so chromium (III) sulfide exists and can be obtained under anhydrous conditions, although not from simple substances, since it decomposes when heated, but according to the reaction: 2CrCl 3 (cr) + 2H 2 S (gas) = Cr 2 S 3 (cr) + 6HCl. Oxidative properties trivalent chromium is not enough for solutions of its salts to react with copper, but with zinc such a reaction takes place: 2CrCl 3 + Zn = 2CrCl 2 + ZnCl 2.

Cr2O3 – an amphoteric oxide of green color, has a very strong crystal lattice, therefore it exhibits chemical activity only in the amorphous state. Reacts mainly when alloyed with acidic and basic oxides, with acids and alkalis, as well as with compounds having acidic or basic functions:

Cr 2 O 3 + 3K 2 S 2 O 7 = Cr 2 (SO 4) 3 + 3K 2 SO 4; Cr 2 O 3 + K 2 CO 3 = 2KCrO 2 + CO 2.

Cr(OH) 3 (CrO(OH), Cr 2 O 3 *nH 2 O) – amphoteric hydroxide gray-blue color. Dissolves in both acids and alkalis. When dissolved in alkalis, hydroxo complexes are formed in which the chromium cation has a coordination number of 4 or 6:

Cr(OH) 3 + NaOH = Na; Cr(OH) 3 + 3NaOH = Na 3.

Hydroxo complexes are easily decomposed by acids, with strong and weak acids the processes are different:

Na + 4HCl = NaCl + CrCl 3 + 4H 2 O; Na + CO 2 = Cr(OH) 3 ↓ + NaHCO 3.

Cr(III) compounds are not only oxidizing agents, but also reducing agents in relation to the conversion to Cr(VI) compounds. The reaction occurs especially easily in an alkaline environment:

2Na 3 + 3Cl 2 + 4NaOH = 2Na 2 CrO 4 + 6NaCl + 8H 2 O E 0 = - 0.72 V.

IN acidic environment: 2Cr 3+ → Cr 2 O 7 2- E 0 = +1.38 V.

Cr +6 . All Cr(VI) compounds are strong oxidizing agents. The acid-base behavior of these compounds is similar to that of sulfur compounds in the same oxidation state. Such similarity in the properties of compounds of elements of the main and secondary subgroups in the maximum positive oxidation state is characteristic of most groups of the periodic system.

CrO3 - a dark red compound, a typical acid oxide. At the melting point it decomposes: 4CrO 3 = 2Cr 2 O 3 + 3O 2.

Example of oxidizing action: CrO 3 + NH 3 = Cr 2 O 3 + N 2 + H 2 O (When heated).

Chromium(VI) oxide easily dissolves in water, adding it and turning into hydroxide:

H2CrO4 - chromic acid is a strong dibasic acid. It is not allocated in free form, because at a concentration above 75%, a condensation reaction occurs with the formation of dichromic acid: 2H 2 CrO 4 (yellow) = H 2 Cr 2 O 7 (orange) + H 2 O.

Further concentration leads to the formation of trichromic (H 2 Cr 3 O 10) and even tetrachromic (H 2 Cr 4 O 13) acids.

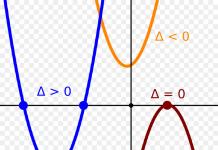

Dimerization of the chromate anion also occurs upon acidification. As a result, salts of chromic acid at pH > 6 exist as yellow chromates (K 2 CrO 4), and at pH< 6 как бихроматы(K 2 Cr 2 O 7) оранжевого цвета. Большинство бихроматов растворимы, а растворимость хроматов чётко соответствует растворимости сульфатов соответствующих металлов. В растворах возможно взаимопревращения соответствующих солей:

2K 2 CrO 4 + H 2 SO 4 = K 2 Cr 2 O 7 + K 2 SO 4 + H 2 O; K 2 Cr 2 O 7 + 2KOH = 2K 2 CrO 4 + H 2 O.

The interaction of potassium dichromate with concentrated sulfuric acid leads to the formation of chromic anhydride, insoluble in it:

K 2 Cr 2 O 7 (crystalline) + + H 2 SO 4 (conc.) = 2CrO 3 ↓ + K 2 SO 4 + H 2 O;

When heated, ammonium dichromate undergoes an intramolecular redox reaction: (NH 4) 2 Cr 2 O 7 = Cr 2 O 3 + N 2 + 4H 2 O.

HALOGENS (“birthing salts”)

The elements are called halogens main subgroup Group VII of the periodic table. These are fluorine, chlorine, bromine, iodine, astatine. The structure of the outer electronic layer of their atoms: ns 2 np 5. Thus, there are 7 electrons at the outer electronic level, and they lack only one electron to reach the stable shell of the noble gas. Being the penultimate elements in the period, halogens have the smallest radius in the period. All this leads to the fact that halogens exhibit the properties of non-metals, have high electronegativity and high ionization potential. Halogens are strong oxidizing agents; they are capable of accepting an electron, becoming an anion with a "1-" charge, or exhibiting a "-1" oxidation state when covalently bonding with less electronegative elements. At the same time, when moving through the group from top to bottom, the atomic radius increases and the oxidizing ability of halogens decreases. If fluorine is the strongest oxidizing agent, then iodine, when interacting with some complex substances, as well as with oxygen and other halogens, exhibits reducing properties.

The fluorine atom is different from the other members of the group. Firstly, it exhibits only a negative oxidation state, since it is the most electronegative element, and secondly, like any element of period II, it has only 4 atomic orbitals at the outer electronic level, three of which are occupied by lone electron pairs, on the fourth there is an unpaired electron, which in most cases is the only valence electron. In the atoms of other elements, at the outer level there is an unfilled d-electron sublevel, where an excited electron can go. Each lone pair gives two electrons when paired, so the main oxidation states of chlorine, bromine and iodine, in addition to “-1”, are “+1”, “+3”, “+5”, “+7”. Less stable, but fundamentally achievable, are the oxidation states “+2”, “+4” and “+6”.

How simple substances All halogens are diatomic molecules with single bonds between the atoms. The dissociation energies of bonds in the series of molecules F 2 , Cl 2 , Br 2 , J 2 are as follows: 151 kJ/mol, 239 kJ/mol, 192 kJ/mol, 149 kJ/mol. The monotonic decrease in bond energy when going from chlorine to iodine is easily explained by an increase in bond length due to an increase in the atomic radius. The abnormally low binding energy in the fluorine molecule has two explanations. The first concerns the fluorine molecule itself. As already mentioned, fluorine has a very small atomic radius and as many as seven electrons on the outer level, therefore, when atoms approach each other during the formation of a molecule, electron-electron repulsion occurs, as a result of which the orbitals do not completely overlap, and the bond order in the fluorine molecule is slightly less than one. According to the second explanation, in the molecules of the remaining halogens there is an additional donor-acceptor overlap between the lone electron pair of one atom and the free d-orbital of another atom, two such opposite interactions per molecule. Thus, the bond in the molecules of chlorine, bromine and iodine is defined as almost triple in terms of the presence of interactions. But donor-acceptor overlap occurs only partially, and the bond has an order (for a chlorine molecule) of 1.12.

Physical properties: Under normal conditions, fluorine is a difficult to liquefy gas (boiling point of which is -187 0 C) of light yellow color, chlorine is an easily liquefied gas (boiling point is -34.2 0 C) yellow-green gas, bromine is a brown, easily evaporating liquid. , iodine is a gray solid with a metallic luster. In the solid state, all halogens form a molecular crystal lattice characterized by weak intermolecular interactions. In this connection, iodine has a tendency to sublimate - when heated at atmospheric pressure it turns into gaseous state(forms purple vapors) bypassing the liquid. When moving through the group from top to bottom, the melting and boiling points increase both due to an increase in the molecular weight of the substances and due to the strengthening of the van der Waals forces acting between the molecules. The magnitude of these forces is greater, the greater the polarizability of the molecule, which, in turn, increases with increasing radius of the atom.

All halogens are poorly soluble in water, but well soluble in non-polar organic solvents, for example, carbon tetrachloride. Poor solubility in water is due to the fact that when a cavity is formed for the dissolution of a halogen molecule, water loses sufficiently strong hydrogen bonds, in exchange for which no strong interactions arise between its polar molecule and the non-polar halogen molecule. The dissolution of halogens in non-polar solvents corresponds to the situation: “like dissolves in like,” when the nature of the breaking and forming bonds is the same.

Chromium (Cr) is an element with atomic number 24 and atomic mass 51,996 side subgroup of the sixth group of the fourth period of the periodic system of chemical elements of D. I. Mendeleev. Chrome is a hard metal with a bluish-white color. Has high chemical resistance. At room temperature, Cr is resistant to water and air. This element is one of the most important metals used in industrial alloying of steels. Chromium compounds have bright colors of various colors, which is why it got its name. After all, translated from Greek, “chrome” means “paint”.

There are 24 known isotopes of chromium from 42Cr to 66Cr. Stable natural isotopes 50Cr (4.31%), 52Cr (87.76%), 53Cr (9.55%) and 54Cr (2.38%). Of the six artificial radioactive isotopes the most important is 51Cr with a half-life of 27.8 days. It is used as an isotope indicator.

Unlike the metals of antiquity (gold, silver, copper, iron, tin and lead), chromium has its own “discoverer”. In 1766, a mineral was found in the vicinity of Yekaterinburg, which was called “Siberian red lead” - PbCrO4. In 1797, L. N. Vauquelin discovered element No. 24 in the mineral crocoite, a natural lead chromate. Around the same time (1798), independently of Vauquelin, chromium was discovered by German scientists M. G. Klaproth and Lowitz in a sample of heavy black mineral (it was chromite FeCr2O4), found in the Urals. Later in 1799, F. Tassert discovered a new metal in the same mineral found in southeastern France. It is believed that it was Tassert who first managed to obtain relatively pure metal chromium.

Metal chromium is used for chrome plating, and also as one of the most important components of alloy steels (in particular stainless steels). In addition, chromium has found application in a number of other alloys (acid-resistant and heat-resistant steels). After all, the introduction of this metal into steel increases its resistance to corrosion, both in aquatic environments at ordinary temperatures, and in gases at elevated temperatures. Chromium steels are characterized by increased hardness. Chromium is used in thermochrome plating, a process in which the protective effect of Cr is due to the formation of a thin but durable oxide film on the surface of the steel, which prevents the interaction of the metal with the environment.

Chromium compounds are also widely used; chromites are successfully used in the refractory industry: open-hearth furnaces and other metallurgical equipment are lined with magnesite-chromite bricks.

Chromium is one of the biogenic elements that are constantly included in the tissues of plants and animals. Plants contain chromium in their leaves, where it is present in the form of a low-molecular complex not associated with subcellular structures. Until now, scientists have not been able to prove the necessity of this element for plants. However, in animals, Cr is involved in the metabolism of lipids, proteins (part of the enzyme trypsin), and carbohydrates (a structural component of the glucose-resistant factor). It is known that only trivalent chromium is involved in biochemical processes. Like most other important nutrients, chromium enters the animal or human body through food. A decrease in this microelement in the body leads to slower growth, a sharp increase in blood cholesterol levels and a decrease in the sensitivity of peripheral tissues to insulin.

At the same time, chromium in its pure form is very toxic - Cr metal dust irritates lung tissue, chromium (III) compounds cause dermatitis. Chromium (VI) compounds lead to various human diseases, including cancer.

Biological properties

Chromium is an important biogenic element, which is certainly included in the tissues of plants, animals and humans. The average content of this element in plants is 0.0005%, and almost all of it accumulates in the roots (92-95%), the rest is contained in the leaves. Higher plants do not tolerate concentrations of this metal above 3∙10-4 mol/l. In animals, the chromium content ranges from ten thousandths to ten millionths of a percent. But in plankton, the coefficient of chromium accumulation is amazing - 10,000-26,000. In the adult human body, the Cr content ranges from 6 to 12 mg. And quite accurately physiological need It is not installed in chrome for humans. It largely depends on the diet - when eating food high in sugar, the body's need for chromium increases. It is generally accepted that a person needs approximately 20–300 mcg of this element per day. Like other biogenic elements, chromium can accumulate in body tissues, especially in hair. It is in them that the chromium content indicates the degree of supply of the body with this metal. Unfortunately, with age, the “reserves” of chromium in tissues are depleted, with the exception of the lungs.

Chromium is involved in the metabolism of lipids, proteins (present in the enzyme trypsin), carbohydrates (is structural component glucose-resistant factor). This factor ensures the interaction of cellular receptors with insulin, thereby reducing the body's need for it. Glucose tolerance factor (GTF) enhances the action of insulin in all metabolic processes involving it. In addition, chromium takes part in the regulation of cholesterol metabolism and is an activator of certain enzymes.

The main source of chromium in animals and humans is food. Scientists have found that the concentration of chromium in plant foods is significantly lower than in animal foods. The richest sources of chromium are brewer's yeast, meat, liver, legumes and whole unprocessed grains. A decrease in the content of this metal in food and blood leads to a decrease in growth rate, an increase in cholesterol in the blood, and a decrease in the sensitivity of peripheral tissues to insulin (diabetes-like state). In addition, the risk of developing atherosclerosis and disorders of higher nervous activity increases.

However, even at concentrations of a fraction of a milligram per cubic meter in the atmosphere, all chromium compounds have toxic effect on the body. Poisoning with chromium and its compounds is common during their production, in mechanical engineering, metallurgy, and in the textile industry. The degree of toxicity of chromium depends on chemical structure its compounds - dichromates are more toxic than chromates, Cr+6 compounds are more toxic than Cr+2 and Cr+3 compounds. Signs of poisoning include a feeling of dryness and pain in the nasal cavity, a sore throat, difficulty breathing, coughing and similar symptoms. If there is a slight excess of chromium vapor or dust, the signs of poisoning disappear soon after work in the workshop stops. With prolonged constant contact with chromium compounds, signs of chronic poisoning appear - weakness, constant headaches, weight loss, dyspepsia. Disturbances in the functioning of the gastrointestinal tract, pancreas, and liver begin. Bronchitis, bronchial asthma, and pneumosclerosis develop. Skin diseases appear - dermatitis, eczema. In addition, chromium compounds are dangerous carcinogens that can accumulate in body tissues, causing cancer.

Prevention of poisoning includes periodic medical examinations of personnel working with chromium and its compounds; installation of ventilation, dust suppression and dust collection equipment; use of personal protective equipment (respirators, gloves) by workers.

The root "chrome" in its concept of "color", "paint" is part of many words used in a wide variety of fields: science, technology and even music. So many names of photographic films contain this root: “orthochrome”, “panchrome”, “isopanchrome” and others. The word "chromosome" consists of two Greek words: “chromo” and “soma”. Literally this can be translated as “painted body” or “body that is painted.” The structural element of a chromosome, formed in the interphase of the cell nucleus as a result of chromosome duplication, is called “chromatid”. “Chromatin” is a substance of chromasomes located in the nuclei of plant and animal cells, which is intensely stained with nuclear dyes. “Chromatophores” are pigment cells in animals and humans. In music, the concept of “chromatic scale” is used. “Khromka” is one of the types of Russian accordion. In optics, there are the concepts of “chromatic aberration” and “chromatic polarization”. "Chromatography" - physico-chemical method separation and analysis of mixtures. “Chromoscope” is a device for obtaining a color image by optically combining two or three color-separated photographic images, illuminated through specially selected differently colored filters.

The most toxic is chromium (VI) oxide CrO3; it belongs to hazard class I. Lethal dose for humans (oral) 0.6 g. Ethanol upon contact with freshly prepared CrO3, it ignites!

The most common grade of stainless steel contains 18% Cr, 8% Ni, about 0.1% C. It has excellent resistance to corrosion and oxidation, and retains strength at high temperatures. It is from this steel that the sheets used in the construction of the sculptural group of V.I. were made. Mukhina "Worker and Collective Farm Woman".

Ferrochrome, used in the metallurgical industry in the production of chromium steels, was of very poor quality at the end of the 19th century. This is due to the low chromium content in it - only 7-8%. Then it was called “Tasmanian cast iron” due to the fact that the original iron-chrome ore was imported from Tasmania.

It was previously mentioned that chrome alum is used in tanning leather. Thanks to this, the concept of “chrome” boots appeared. Leather tanned with chromium compounds acquires shine, gloss and strength.

Many laboratories use a “chromic mixture” - a mixture of a saturated solution of potassium dichromate with concentrated sulfuric acid. It is used in degreasing the surfaces of glass and steel laboratory glassware. It oxidizes fat and removes its remains. Just handle this mixture with caution, because it is a mixture of a strong acid and a strong oxidizing agent!

In modern times, wood is still used as building material, because it is inexpensive and easy to process. But it also has many negative properties - susceptibility to fires, fungal diseases that destroy it. To avoid all these troubles, wood is impregnated with special compounds containing chromates and dichromates, plus zinc chloride, copper sulfate, sodium arsenate and some other substances. Thanks to such compositions, wood increases its resistance to fungi and bacteria, as well as to open fire.

Chrome has occupied a special niche in printing. In 1839, it was discovered that paper impregnated with sodium bichromate suddenly turned brown when exposed to bright light. Then it turned out that bichromate coatings on paper, after exposure, do not dissolve in water, but, when wetted, acquire a bluish tint. Printers took advantage of this property. The desired pattern was photographed on a plate with a colloidal coating containing dichromate. The illuminated areas did not dissolve during washing, and the unexposed areas dissolved, and a pattern remained on the plate from which it was possible to print.

Story

The history of the discovery of element No. 24 began in 1761, when in the Berezovsky mine (eastern foot Ural mountains) an unusual red mineral was found near Yekaterinburg, which, when ground into dust, gave a yellow color. The find belonged to St. Petersburg University professor Johann Gottlob Lehmann. Five years later, the scientist delivered the samples to the city of St. Petersburg, where he conducted a series of experiments on them. In particular, he treated the unusual crystals with hydrochloric acid, resulting in a white precipitate in which lead was found. Based on the results obtained, Lehman named the mineral Siberian red lead. This is the story of the discovery of crocoite (from the Greek “krokos” - saffron) - a natural lead chromate PbCrO4.

Interested in this find, Peter Simon Pallas, a German naturalist and traveler, organized and led an expedition of the St. Petersburg Academy of Sciences to the heart of Russia. In 1770, the expedition reached the Urals and visited the Berezovsky mine, where samples of the studied mineral were taken. This is how the traveler himself describes it: “This amazing red lead mineral is not found in any other deposit. When ground into powder it turns yellow and can be used in artistic miniatures.” German enterprise overcame all the difficulties of mining and delivering crocoite to Europe. Despite the fact that these operations took at least two years, soon the carriages of the noble gentlemen of Paris and London were traveling painted with finely ground crocoite. The collections of the mineralogical museums of many universities of the old world have been enriched with the best examples of this mineral from the Russian depths. However, European scientists could not figure out the composition of the mysterious mineral.

This lasted for thirty years, until a sample of Siberian red lead fell into the hands of Nicolas Louis Vauquelin, professor of chemistry at the Paris Mineralogical School, in 1796. After analyzing the crocoite, the scientist found nothing in it except oxides of iron, lead and aluminum. Subsequently, Vauquelin treated crocoite with a solution of potash (K2CO3) and, following the precipitation of a white precipitate of lead carbonate, isolated a yellow solution of an unknown salt. After conducting a series of experiments on treating the mineral with salts of various metals, the professor, using hydrochloric acid, isolated a solution of “red lead acid” - chromium oxide and water (chromic acid exists only in dilute solutions). By evaporating this solution, he obtained ruby-red crystals (chromic anhydride). Further heating of the crystals in a graphite crucible in the presence of coal gave a lot of fused gray needle-shaped crystals - a new, hitherto unknown metal. The next series of experiments showed the high refractoriness of the resulting element and its resistance to acids. The Paris Academy of Sciences immediately witnessed the discovery; the scientist, at the insistence of his friends, gave the name to the new element - chromium (from the Greek “color”, “color”) due to the variety of shades of the compounds it forms. In his further works, Vauquelin confidently stated that the emerald color of some precious stones, as well as natural beryllium and aluminum silicates, is explained by the admixture of chromium compounds in them. An example is emerald, which is a green-colored beryl in which aluminum is partially replaced by chromium.

It is clear that Vauquelin did not obtain pure metal, most likely its carbides, which is confirmed by the needle-shaped shape of light gray crystals. Pure chromium metal was later obtained by F. Tassert, probably in 1800.

Also, independently of Vauquelin, chromium was discovered by Klaproth and Lowitz in 1798.

Being in nature

In the bowels of the earth, chromium is a fairly common element, despite the fact that it is not found in free form. Its clarke (average content in the earth's crust) is 8.3.10-3% or 83 g/t. However, its distribution among breeds is uneven. This element is mainly characteristic of the Earth’s mantle; the fact is that ultramafic rocks (peridotites), which are presumably close in composition to the mantle of our planet, are the richest in chromium: 2 10-1% or 2 kg/t. In such rocks, Cr forms massive and disseminated ores, and the formation of the largest deposits of this element is associated with them. The chromium content is also high in basic rocks (basalts, etc.) 2 10-2% or 200 g/t. Much less Cr is found in acidic rocks: 2.5 10-3%, sedimentary rocks (sandstones) - 3.5 10-3%, shales also contain chromium - 9 10-3%.

It can be concluded that chromium is a typical lithophile element and is almost entirely contained in deep minerals in the Earth’s interior.

There are three main chromium minerals: magnochromite (Mn, Fe)Cr2O4, chromopicotite (Mg, Fe)(Cr, Al)2O4 and aluminochromite (Fe, Mg)(Cr, Al)2O4. These minerals have a single name - chrome spinel and the general formula (Mg, Fe)O (Cr, Al, Fe)2O3. By appearance they are indistinguishable and are inaccurately called "chromites". Their composition is variable. The content of the most important components varies (weight %): Cr2O3 from 10.5 to 62.0; Al2O3 from 4 to 34.0; Fe2O3 from 1.0 to 18.0; FeO from 7.0 to 24.0; MgO from 10.5 to 33.0; SiO2 from 0.4 to 27.0; TiO2 impurities up to 2; V2O5 up to 0.2; ZnO up to 5; MnO up to 1. Some chromium ores contain 0.1-0.2 g/t of platinum group elements and up to 0.2 g/t of gold.

In addition to various chromites, chromium is part of a number of other minerals - chrome vesuvian, chrome chlorite, chrome tourmaline, chrome mica (fuchsite), chrome garnet (uvarovite), etc., which often accompany ores, but are not of industrial importance. Chromium is a relatively weak aquatic migrant. Under exogenous conditions, chromium, like iron, migrates in the form of suspensions and can precipitate in clays. The most mobile form is chromates.

Of practical importance, perhaps, is only chromite FeCr2O4, which belongs to spinels - isomorphic minerals of the cubic system with the general formula MO Me2O3, where M is a divalent metal ion, and Me is a trivalent metal ion. In addition to spinels, chromium is found in many much less common minerals, for example, melanochroite 3PbO 2Cr2O3, vokelenite 2(Pb,Cu)CrO4(Pb,Cu)3(PO4)2, tarapacaite K2CrO4, ditzeite CaIO3 CaCrO4 and others.

Chromites are usually found in the form of granular masses of black color, less often - in the form of octahedral crystals, have a metallic luster, and occur in the form of continuous masses.

At the end of the 20th century, chromium reserves (identified) in almost fifty countries of the world with deposits of this metal amounted to 1674 million tons. The leading position is occupied by the Republic of South Africa - 1050 million tons, where the main contribution is made by the Bushveld complex (about 1000 million tons ). The second place in chrome resources belongs to Kazakhstan, where in the Aktobe region (Kempirsay massif) ore is mined very high quality. Other countries also have reserves of this element. Turkey (in Guleman), Philippines on the island of Luzon, Finland (Kemi), India (Sukinda), etc.

Our country has its own developed chromium deposits in the Urals (Donskoye, Saranovskoye, Khalilovskoye, Alapaevskoye and many others). Moreover, in early XIX centuries, it was the Ural deposits that were the main sources of chromium ores. Only in 1827 did the American Isaac Tison discover large deposit chrome ore on the Maryland-Pennsylvania border, seizing a mining monopoly for many years. In 1848, deposits of high-quality chromite were found in Turkey, near Bursa, and soon (after the depletion of the Pennsylvania deposit) it was this country that took over the role of monopolist. This continued until 1906, when rich deposits of chromite were discovered in South Africa and India.

Application

Total consumption of pure chromium metal today is approximately 15 million tons. The production of electrolytic chromium - the purest - accounts for 5 million tons, which is a third of total consumption.

Chromium is widely used to alloy steels and alloys, giving them corrosion and heat resistance. More than 40% of the resulting pure metal is consumed in the production of such “superalloys”. The most well-known resistance alloys are nichrome with a Cr content of 15-20%, heat-resistant alloys - 13-60% Cr, stainless alloys - 18% Cr and ball bearing steels 1% Cr. The addition of chromium to conventional steels improves their physical properties and makes the metal more susceptible to heat treatment.

Metallic chromium is used for chrome plating - applying a thin layer of chromium to the surface of steel alloys in order to increase the corrosion resistance of these alloys. The chrome plating is highly resistant to moisture. atmospheric air, salty sea air, water, nitric and most organic acids. Such coatings have two purposes: protective and decorative. The thickness of the protective coatings is about 0.1 mm; they are applied directly to the product and give it increased wear resistance. Decorative coatings have an aesthetic value; they are applied to a layer of another metal (copper or nickel), which actually performs a protective function. The thickness of such a coating is only 0.0002–0.0005 mm.

Chromium compounds are also actively used in various fields.

The main chromium ore - chromite FeCr2O4 is used in the production of refractories. Magnesite-chromite bricks are chemically passive and heat-resistant; they can withstand sudden, repeated temperature changes, which is why they are used in the structures of the arches of open-hearth furnaces and the working space of other metallurgical devices and structures.

The hardness of chromium (III) oxide crystals - Cr2O3 is comparable to the hardness of corundum, which ensures its use in the compositions of grinding and lapping pastes used in mechanical engineering, jewelry, optical and watch industries. It is also used as a catalyst for the hydrogenation and dehydrogenation of certain organic compounds. Cr2O3 is used in painting as a green pigment and for coloring glass.

Potassium chromate - K2CrO4 is used in leather tanning, as a mordant in the textile industry, in the production of dyes, and in wax bleaching.

Potassium dichromate (chrompic) - K2Cr2O7 is also used for tanning leather, as a mordant for dyeing fabrics, and is a corrosion inhibitor for metals and alloys. Used in the manufacture of matches and for laboratory purposes.

Chromium (II) chloride CrCl2 is a very strong reducing agent, easily oxidized even by atmospheric oxygen, which is used in gas analysis for the quantitative absorption of O2. In addition, it is used to a limited extent in the production of chromium by electrolysis of molten salts and chromatometry.

Chromium-potassium alum K2SO4.Cr2(SO4)3 24H2O is used mainly in the textile industry - for tanning leather.

Anhydrous chromium chloride CrCl3 is used to apply chromium coatings to the surface of steels by chemical vapor deposition and is a component of some catalysts. CrCl3 hydrates are a mordant for dyeing fabrics.

Various dyes are made from lead chromate PbCrO4.

A solution of sodium bichromate is used to clean and etch the surface of steel wire before galvanizing, and also to brighten brass. Chromic acid is obtained from sodium dichromate, which is used as an electrolyte in chrome plating of metal parts.

Production

In nature, chromium is found mainly in the form of chromium iron ore FeO∙Cr2O3; when it is reduced with coal, an alloy of chromium with iron is obtained - ferrochrome, which is directly used in the metallurgical industry in the production of chromium steels. The chromium content in this composition reaches 80% (by weight).

The reduction of chromium (III) oxide with coal is intended to obtain high-carbon chromium necessary for the production of special alloys. The process is carried out in an electric arc furnace.

To obtain pure chromium, chromium(III) oxide is first prepared and then reduced by an aluminothermic method. In this case, a mixture of powdered or in the form of aluminum shavings (Al) and a charge of chromium oxide (Cr2O3) are first heated to a temperature of 500-600 ° C. Then, reduction is initiated with a mixture of barium peroxide with aluminum powder, or by igniting part of the charge, followed by adding the remaining part . In this process, it is important that the resulting thermal energy is sufficient to melt the chromium and separate it from the slag.

Cr2O3 + 2Al = 2Cr + 2Al2O3

The chromium obtained in this way contains a certain amount of impurities: iron 0.25-0.40%, sulfur 0.02%, carbon 0.015-0.02%. The content of pure substance is 99.1–99.4%. This chromium is fragile and easily ground into powder.

The reality of this method was proven and demonstrated back in 1859 by Friedrich Wöhler. On an industrial scale, aluminothermic reduction of chromium became possible only after a method for producing cheap aluminum became available. Goldschmidt was the first to develop a safe way to regulate the highly exothermic (hence explosive) reduction process.

When it is necessary to obtain high-purity chromium, industry uses electrolytic methods. Electrolysis is carried out using a mixture of chromic anhydride, chromoammonium alum or chromium sulfate with dilute sulfuric acid. Chromium deposited on aluminum or stainless steel cathodes during electrolysis contains dissolved gases as impurities. Purity of 99.90–99.995% can be achieved using high-temperature (1500-1700° C) purification in a hydrogen flow and vacuum degassing. Advanced electrolytic chromium refining techniques remove sulfur, nitrogen, oxygen and hydrogen from the raw product.

In addition, it is possible to obtain Cr metal by electrolysis of CrCl3 or CrF3 melts in a mixture with potassium, calcium, and sodium fluorides at a temperature of 900 ° C in an argon environment.

The possibility of the electrolytic method of obtaining pure chromium was proved by Bunsen in 1854, by subjecting to electrolysis aqueous solution chromium chloride.

The industry also uses a silicothermic method for producing pure chromium. In this case, chromium is reduced from oxide by silicon:

2Cr2O3 + 3Si + 3CaO = 4Cr + 3CaSiO3

Chromium is silicothermally smelted in arc furnaces. The addition of quicklime allows you to convert refractory silicon dioxide into low-melting calcium silicate slag. The purity of silicothermic chromium is approximately the same as aluminothermic chromium, however, naturally, the silicon content in it is slightly higher and the aluminum content is slightly lower.

Cr can also be obtained by the reduction of Cr2O3 with hydrogen at 1500° C, the reduction of anhydrous CrCl3 with hydrogen, alkali or alkaline earth metals, magnesium and zinc.